NEWS DETAIL

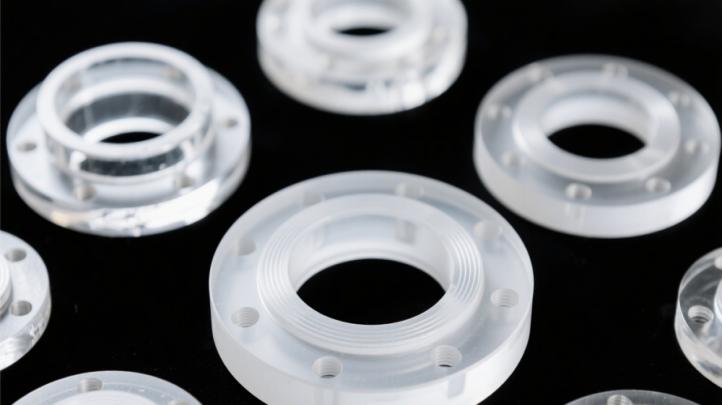

Should the Surface of Quartz Flange be Polished or Treated?

Should it be polished? Or is that an over-engineered luxury? You’d be surprised how this seemingly small detail leads to real friction in labs, fabs, and even procurement offices. Whether you're in semiconductor manufacturing, vacuum systems, or advanced optics, the answer isn't one-size-fits-all. This article unpacks the debate—layer by layer—so you can decide with full clarity whether polished quartz flanges are essential for your process, or simply optional.

Is Polishing Quartz Flange Surfaces Necessary?

Let’s start with the obvious question: is polishing necessary? Well, it depends.

Polishing improves the surface smoothness of quartz, reducing microscopic pits, scratches, and roughness that can trap particles or compromise seals. In environments where ultra-clean operation or vacuum integrity is crucial—think semiconductor wafer processing chambers or high-precision optical paths—an unpolished surface may fall short.

But in less demanding environments (e.g., some chemical reactors or support structures), a flame-cut or ground finish may be more than sufficient. Over-specifying a polished finish could just be adding cost with no real return.

Which Applications Demand Polishing?

Here’s where polishing moves from “nice to have” to “non-negotiable”:

Semiconductor Processing: Chambers, wafer boats, or flange joints that require extreme cleanliness benefit greatly from optical-grade polishing. It minimizes particle shedding and makes surfaces easier to clean.

Vacuum Systems: Even tiny surface flaws can cause virtual leaks or disrupt gasket sealing. A smooth, lapped surface ensures reliable vacuum sealing.

Optical and UV Systems: In light-sensitive paths, polished surfaces reduce scattering and distortion, especially when the flange also functions as a mounting or viewing port.

Polishing may also be required by customers who follow strict internal SOPs or supplier quality agreements. In such cases, skipping it could be a deal-breaker.

Potential Risks and Limitations of Unpolished Quartz Flanges

▪ Using unpolished flanges isn’t just a cosmetic concern—it can lead to real-world issues depending on the application:

▪ Seal failure due to rough surface textures causing uneven gasket compression.

▪ Particle generation in cleanroom environments from micro-abrasion.

▪ Cleaning difficulty, especially after chemical exposure or thermal cycling.

▪ Risk of contamination, where micro-pits trap residues that off-gas or leach out.

That said, not every unpolished surface is automatically a liability. Some processes tolerate or even prefer a lightly ground finish for better mechanical grip or lower stress concentration.

Is Surface Polishing Worth the Investment?

Let’s talk dollars and downtime. Polishing quartz isn’t cheap—it adds extra labor, slows down production lead times, and increases rejection risk during inspection (a tiny scratch on a polished surface often means a failed part).

So, is it worth it?

Yes, if the polishing enhances yield, process reliability, or equipment uptime. For example, a failed seal in a vacuum chamber could lead to hours of downtime and tens of thousands in losses. In that context, the polishing cost is negligible.

No, if your application doesn’t involve tight tolerances, high vacuum, or particle-sensitive operations. Spending 20–40% more on a highly polished flange may be unnecessary for bulk chemical processing or furnace insulation rings.

The ROI of polishing should always be viewed through the lens of performance gain, not aesthetics or habit.

Different Standards for Quartz Flange Surface Treatments

There’s no single global standard for quartz flange finishes, but here are some trends across industries:

▪ Semiconductor OEMs often require Ra ≤ 0.5 µm or better, sometimes specifying fire-polishing or even double-sided optical polishing.

▪ Vacuum hardware manufacturers may call for surface lapping to enhance seal performance.

▪ Research institutions often develop custom specs based on experimental setups.

▪ Chemical processing users typically accept flame-cut or sandblasted finishes unless handling ultra-pure chemicals.

Some suppliers provide polishing as an optional service tier, while others bundle it as standard in high-purity product lines. It's important to align the spec not just with the application—but also with what’s technically and economically reasonable.

There’s no universal answer to whether quartz flanges should be polished or treated—because the “right” decision depends on context.

If your process is sensitive to particles, vacuum leaks, or optical clarity, a polished surface isn’t just preferred—it’s essential. But if you're dealing with more forgiving environments where mechanical fit, heat resistance, and cost matter more than cosmetic smoothness, a raw or lightly processed finish may be perfectly acceptable.

Polishing is neither a luxury nor a default, it’s a design choice. The best approach? Understand the functional demands of your system, weigh the trade-offs, and make a call based on what matters for your process—not just what looks good on paper.