Ire Polished Boat

Name:

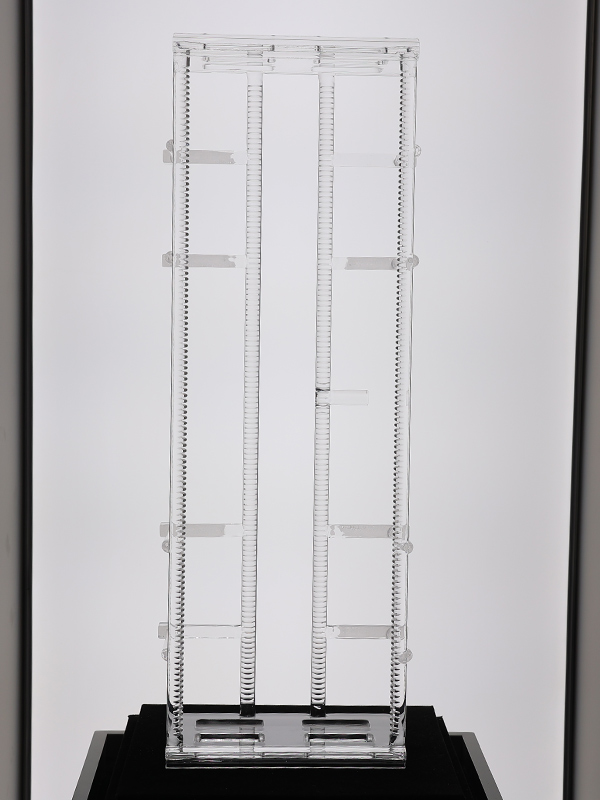

Horizontal IRE Polished Quartz Boat

Function and Application:

Quartz boats are used in the diffusion process of PERC (Passivated Emitter and Rear Cell) solar cells, serving to hold silicon wafers while they enter the diffusion furnace. This is a high-temperature process.

Performance Requirements:

Corrosion resistance, low impurity content, high-temperature resistance, and good light transmittance.

-

No.5177 Qianghua West Road, Dongqian Street, Nanxun District, Huzhou City, Zhejiang Province

-

+86-572-3032373

+86-572-3033016

The Horizontal IRE Polished Quartz Boat is a precision-engineered support structure designed to hold silicon wafers during the high-temperature diffusion process of PERC (Passivated Emitter and Rear Cell) solar cells. Crafted from high-purity quartz, it provides exceptional thermal stability, chemical resistance, and low impurity levels. The polished surface ensures minimal contamination, while its accurate spacing allows uniform wafer exposure and heat distribution, optimizing yield and process consistency.

Polished Quartz vs Regular Quartz: The Difference in Solar Manufacturing

Quartz is a fundamental material in high-temperature applications, especially in solar photovoltaic (PV) manufacturing. However, not all quartz is created equal. The key distinction lies between polished quartz and regular quartz.

Regular quartz is suitable for general use but may have surface imperfections and microscopic roughness. In high-temperature PV processes, these imperfections can cause silicon contamination, uneven heat distribution, and potential defects in solar wafers.

Polished quartz, on the other hand, undergoes a precise surface treatment that creates a smooth, uniform finish. This reduces particle adhesion, minimizes chemical reactions with silicon, and improves thermal uniformity. As a result, polished quartz ensures higher wafer yields, cleaner production environments, and better overall efficiency for solar cells.

In short, while regular quartz works for basic applications, polished quartz is essential for precision and quality in advanced photovoltaic manufacturing. Choosing the right type of quartz directly impacts product reliability and performance in the solar industry.