SIC Boat

Name:

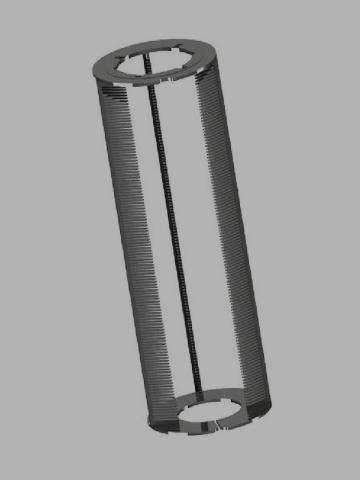

SiC Boat

Function and Application:

The silicon carbide (SiC) boat is a high-temperature-resistant container made from silicon carbide. With its high melting point (about 2700 °C), chemical inertness, and excellent thermal stability, it is widely used in semiconductor monocrystalline silicon and silicon carbide wafer growth. SiC boats effectively prevent the diffusion of impurities from the substrate material, improving wafer yield and extending component service life. Typical application environments include high temperatures, as well as oxidizing and corrosive atmospheres.

Performance Requirements:

High-temperature resistance and corrosion resistance.

-

No.5177 Qianghua West Road, Dongqian Street, Nanxun District, Huzhou City, Zhejiang Province

-

+86-572-3032373

+86-572-3033016

Silicon Carbide Wafer Boats are engineered high-temperature carriers designed to support wafers during demanding thermal processes such as crystal growth, diffusion, and annealing. Made from high-purity silicon carbide with a melting point near 2700 °C, these boats deliver outstanding chemical inertness, superior thermal stability, and strong resistance to oxidation and corrosion in harsh furnace environments.

Their robust construction minimizes impurity diffusion and contamination, preserving wafer integrity and enhancing yield. Precision design ensures uniform wafer spacing and consistent gas flow, supporting stable thermal profiles and repeatable process results. With excellent durability under aggressive atmospheres, Silicon Carbide Wafer Boats extend service life and reduce maintenance needs, making them ideal for advanced semiconductor manufacturing.

SiC Wafer Boats vs Quartz or Ceramic Boats

In semiconductor manufacturing and laboratory research, the choice of wafer boat material is crucial for thermal stability, chemical resistance, and process reliability. SiC (Silicon Carbide) wafer boats offer several advantages over traditional quartz or ceramic boats.

Thermal Performance: SiC boats can withstand extremely high temperatures without deforming or cracking. Their high thermal conductivity ensures uniform heat distribution, which is essential for consistent wafer processing. Quartz and ceramic boats, by comparison, have lower thermal conductivity and are more prone to thermal shock.

Chemical Resistance: SiC is highly inert, resisting corrosion from acids, bases, and other aggressive chemicals used in lab or industrial processes. Quartz is relatively inert but can be attacked under certain chemical conditions, and ceramics may degrade over time.

Durability: SiC boats have superior mechanical strength and wear resistance, reducing breakage and extending equipment lifespan. Quartz and ceramic boats are more fragile, especially under repeated thermal cycling.

In short, while quartz and ceramic boats can work for standard applications, SiC wafer boats provide enhanced reliability, longevity, and performance, making them the preferred choice for high-temperature, high-precision semiconductor and laboratory processes.