SIC Boat

Name:

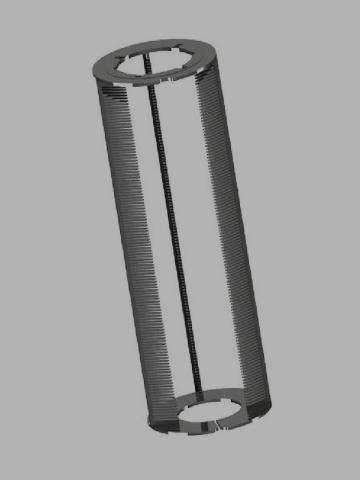

SiC Boat

Function and Application:

The silicon carbide (SiC) boat is a high-temperature-resistant container made from silicon carbide. With a high melting point (approximately 2700 °C), chemical inertness, and excellent thermal stability, it is widely used in the growth of semiconductor monocrystalline silicon and silicon carbide wafers. SiC boats effectively prevent the diffusion of impurities from the substrate, improving wafer yield and extending component service life. Typical application environments include high temperatures, as well as oxidizing and corrosive atmospheres.

Performance Requirements:

High-temperature resistance and corrosion resistance.

-

No.5177 Qianghua West Road, Dongqian Street, Nanxun District, Huzhou City, Zhejiang Province

-

+86-572-3032373

+86-572-3033016

Silicon Carbide Ceramic Wafer Boats are high-performance carriers engineered to securely hold semiconductor wafers during high-temperature processes such as diffusion, annealing, and chemical vapor deposition. Constructed from advanced silicon carbide ceramic, these boats provide exceptional thermal conductivity, outstanding chemical inertness, and superior resistance to oxidation and thermal shock.

Their robust ceramic structure ensures precise wafer spacing and dimensional stability, promoting uniform gas flow and consistent temperature distribution critical for high device yields. Resistant to harsh furnace atmospheres and corrosive gases, Silicon Carbide Ceramic Wafer Boats minimize contamination, extend service life, and enhance overall process reliability in semiconductor manufacturing.

SiC Ceramic Wafer Boats in Next-Generation Electronics and Solar

In modern electronics and photovoltaic (solar) manufacturing, the quality and consistency of wafer processing are critical. SiC (Silicon Carbide) ceramic wafer boats have emerged as a key component in these processes due to their high thermal stability, chemical resistance, and mechanical strength.

SiC ceramic boats can withstand extremely high temperatures required for semiconductor fabrication and solar cell production without deforming or cracking. Their excellent thermal conductivity ensures uniform heat distribution, minimizing thermal stress and improving wafer yield.

Additionally, the chemical inertness of SiC prevents contamination from aggressive chemicals, maintaining high-purity conditions essential for next-generation electronics and high-efficiency solar cells. The durable and wear-resistant construction also extends the lifespan of processing equipment, reducing downtime and maintenance costs.

By combining reliability, precision, and durability, SiC ceramic wafer boats play an indispensable role in the production of advanced electronics and solar cells, helping manufacturers achieve higher efficiency, improved quality, and consistent performance.