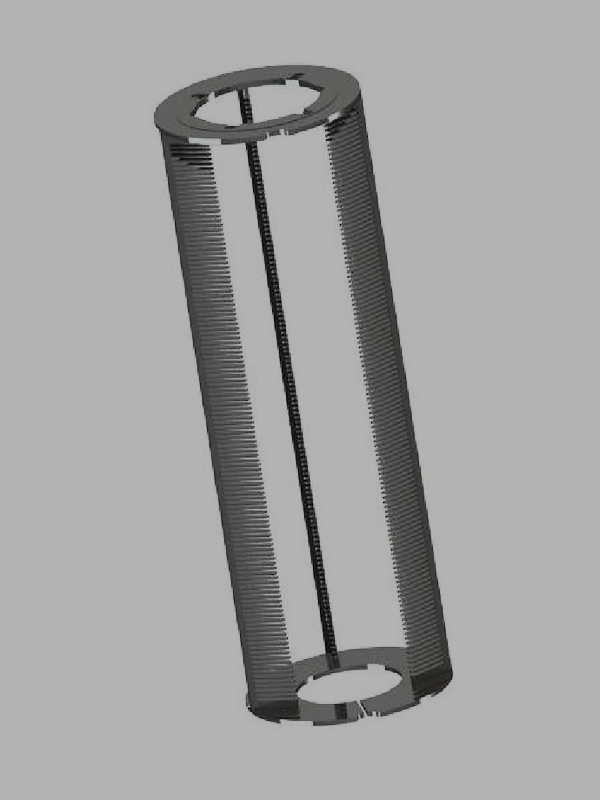

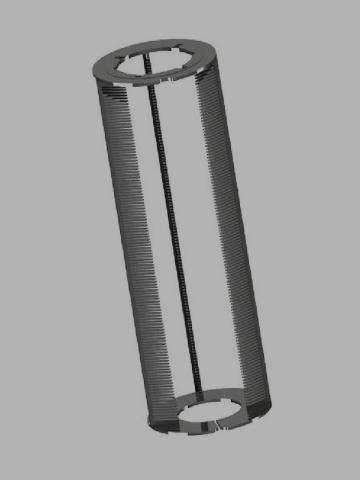

SIC Boat

Name:

SiC Boat

Function and Application:

The silicon carbide (SiC) boat is a high-temperature-resistant container made from silicon carbide. With a high melting point (approximately 2700 °C), chemical inertness, and excellent thermal stability, it is widely used in the growth of semiconductor monocrystalline silicon and silicon carbide wafers. SiC boats effectively prevent the diffusion of impurities from the substrate, improving wafer yield and extending component service life. Typical application environments include high temperatures, as well as oxidizing and corrosive atmospheres.

Performance Requirements:

High-temperature resistance and corrosion resistance.

-

No.5177 Qianghua West Road, Dongqian Street, Nanxun District, Huzhou City, Zhejiang Province

-

+86-572-3032373

+86-572-3033016

Silicon Boats for Vertical Furnaces are precision-engineered carriers designed to securely hold wafers or substrates during high-temperature processes such as diffusion, oxidation, and annealing. Constructed from high-purity silicon or silicon-based materials, these boats deliver excellent thermal stability and conductivity, ensuring uniform heat distribution and minimal thermal stress.

Their robust design resists deformation and contamination, maintaining precise wafer spacing to optimize gas flow and process uniformity. Ideal for demanding vertical furnace applications, these boats enhance process consistency, improve wafer yield, and extend operational reliability in semiconductor manufacturing.

Innovations in Vertical Furnace Processing with Silicon Boats

In semiconductor manufacturing and high-temperature laboratory applications, vertical furnaces are widely used for processes such as wafer diffusion, oxidation, and crystal growth. A critical component in these systems is the silicon boat, which provides a stable and high-purity support for wafers during high-temperature operations.

Recent innovations in silicon boat design and materials have significantly improved vertical furnace efficiency and process reliability. Advanced silicon boats now feature optimized thermal conductivity, ensuring uniform heat distribution across all wafers. This minimizes thermal stress and improves product consistency.

Additionally, improvements in mechanical strength and surface finish have enhanced durability, reducing the risk of cracking or contamination during repeated high-temperature cycles. High-purity silicon also maintains chemical inertness, preventing unwanted reactions and preserving wafer integrity.

These innovations enable manufacturers to achieve higher yields, better wafer quality, and reduced downtime, making silicon boats an essential element in modern vertical furnace processing.