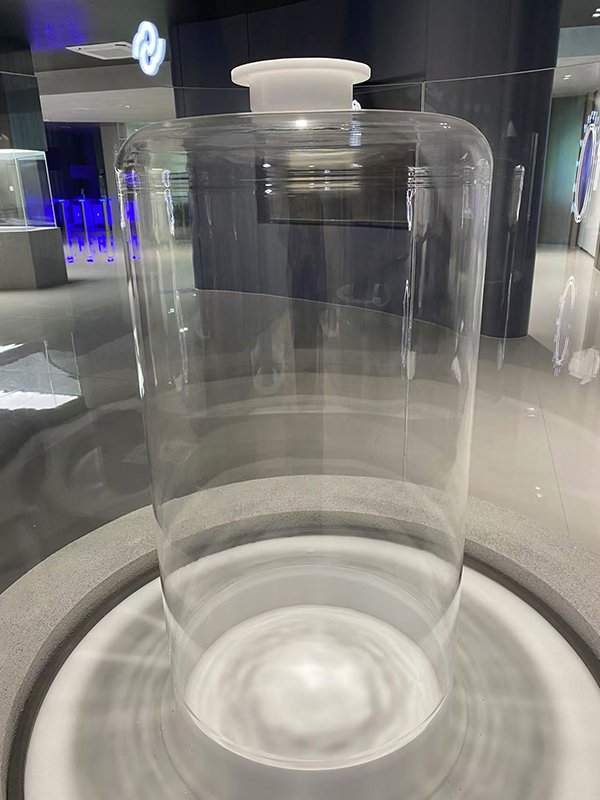

Bell Jar

Name:

12-inch Quartz Bell Jar

Function & Application:

The 12-inch quartz bell jar serves as a core component in high-temperature epitaxial equipment. It performs key functions such as sealing the reaction chamber, withstanding extreme thermal stress, and optimizing thermal field and gas flow design. It is applied in epitaxial growth processes, which are high-temperature processes.

Performance Requirements:

High temperature resistance, corrosion resistance, excellent thermal stability, and low impurity content.

-

No.5177 Qianghua West Road, Dongqian Street, Nanxun District, Huzhou City, Zhejiang Province

-

+86-572-3032373

+86-572-3033016

The quartz bell jars are essential components designed for high-temperature semiconductor and photovoltaic processing systems requiring larger wafer capacities. Manufactured from high-purity fused quartz, these bell jars provide outstanding thermal shock resistance, chemical inertness, and mechanical strength.

Their expanded diameter allows for efficient processing of larger wafers or increased batch sizes, while maintaining precise dimensional control and smooth inner surfaces for uniform gas flow and temperature distribution. These tubes excel in diffusion, oxidation, LPCVD, and annealing applications, ensuring consistent process results and high device yields.

What is a Quartz Bell Jar and How it Works

A quartz bell jar is a high-purity, transparent quartz cover used in laboratory and semiconductor applications. Its primary function is to enclose and protect delicate wafers or materials during low-temperature processes, such as photolithography or vacuum experiments. Made from chemically inert quartz, it resists contamination and maintains optical clarity, ensuring precise process control. Quartz bell jars are typically placed over wafers or experimental setups to create a controlled environment, protect against dust or moisture, and allow observation of the process through their clear walls.

Key Points to Cover:

- Material Properties: High optical transparency, chemical inertness, and low impurity content.

- Function: Acts as a protective cover to maintain stable environmental conditions.

- Applications: Semiconductor wafer processing, lab experiments, vacuum testing, and photolithography.

- Advantages over Standard Glass: Higher thermal stability, lower contamination risk, longer lifespan.

- Maintenance Tips: Cleaning procedures and handling precautions to preserve clarity and avoid cracks.