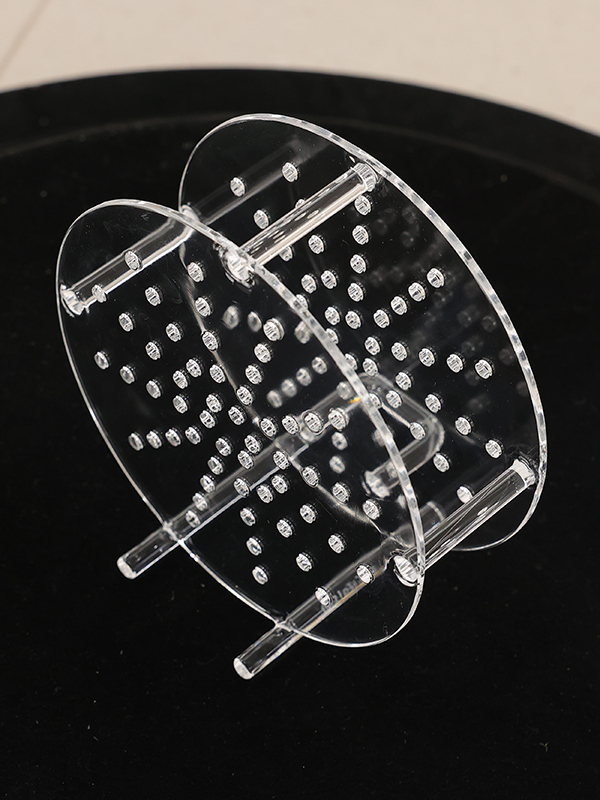

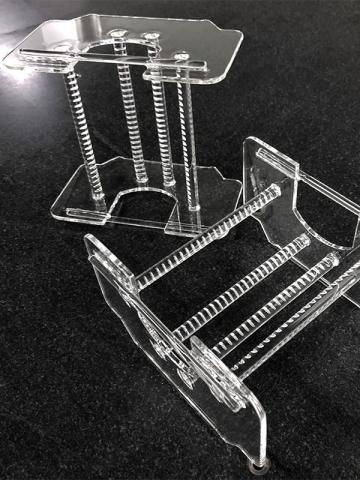

Baffle

Name:

6-inch Quartz Flow Equalization Baffle

Function & Application:

The quartz flow equalization baffle guides and evenly distributes process gases to ensure stable gas flow and temperature during wafer production. It is used to disperse gas flow and maintain consistent gas exposure to wafers inside the quartz boat. This component is applied in diffusion, oxidation, and CVD deposition processes in wafer manufacturing, which are high-temperature processes.

Performance Requirements:

High temperature resistance, corrosion resistance, excellent thermal stability, high optical transparency, and low impurity content.

-

No.5177 Qianghua West Road, Dongqian Street, Nanxun District, Huzhou City, Zhejiang Province

-

+86-572-3032373

+86-572-3033016

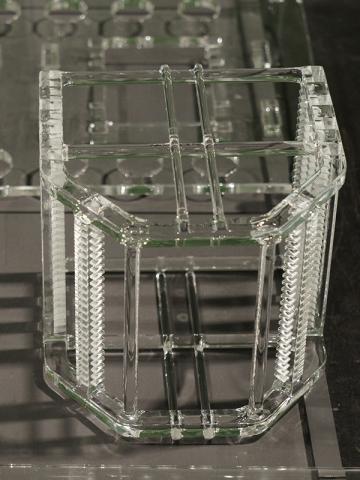

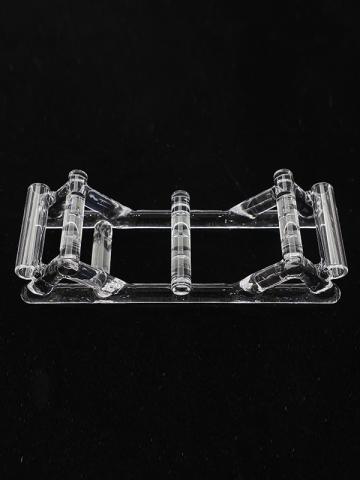

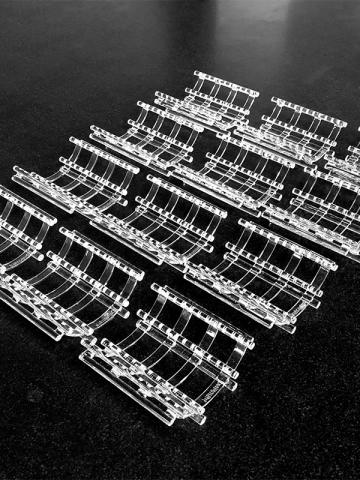

Quartz Flow Equalization Baffles are precision-designed components essential for maintaining uniform gas distribution and temperature stability during high-temperature semiconductor manufacturing processes such as diffusion, oxidation, and CVD deposition. These baffles effectively guide and disperse process gases inside the furnace, ensuring that wafers within the quartz boat receive consistent and even gas exposure.

Manufactured from high-purity fused quartz, they offer excellent thermal stability, corrosion resistance, and low impurity content, which are critical for contamination-free wafer processing. Their high optical transparency facilitates process monitoring, while the durable construction withstands repeated thermal cycling. The baffles’ design promotes optimal gas flow dynamics, contributing to improved layer uniformity, reduced defects, and higher yields in semiconductor fabrication.

Design Considerations for Quartz Flow Equalization Baffles

Material Selection

High-purity quartz is the preferred material due to its excellent thermal stability, chemical resistance, and low impurity content. Using high-purity quartz minimizes contamination risks and ensures long-term performance under harsh conditions.

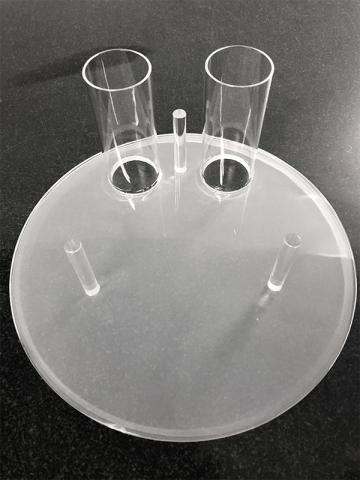

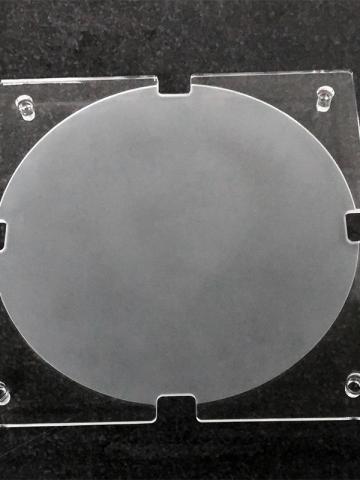

Baffle Thickness and Dimensions

The thickness and overall dimensions of the baffle must be designed to match the furnace specifications and wafer size. Proper thickness ensures structural integrity under high temperatures, while precise dimensions guarantee correct fit within the furnace chamber.

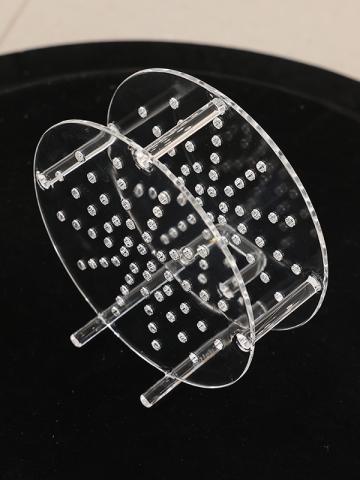

Perforation Patterns

The number, size, and distribution of perforations are critical to gas flow uniformity. Evenly spaced holes allow process gases to be distributed evenly across the wafer surface, preventing hotspots or uneven doping during diffusion, oxidation, or CVD processes.

Surface Treatment

Sandblasted or polished surfaces help reduce particle generation and prevent contamination. Smooth, uniform surfaces also contribute to consistent thermal conduction and laminar gas flow.

Compatibility with Wafer Carriers and Furnace Systems

Designs should consider integration with quartz boats, holders, and furnace automation. Proper alignment ensures minimal turbulence and optimal exposure of wafers to reactive gases.

Thermal and Mechanical Stability

The design must account for thermal expansion and mechanical stress during repeated heating and cooling cycles. A robust, well-engineered structure ensures durability and reliable performance.

Well-designed quartz flow equalization baffles improve gas distribution, thermal stability, and wafer uniformity in semiconductor manufacturing. Careful attention to material, perforation pattern, dimensions, surface treatment, and compatibility is essential for achieving high-quality, repeatable results.