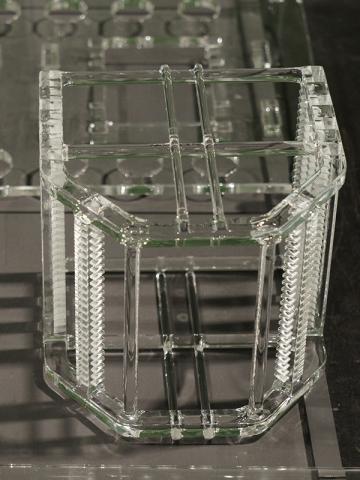

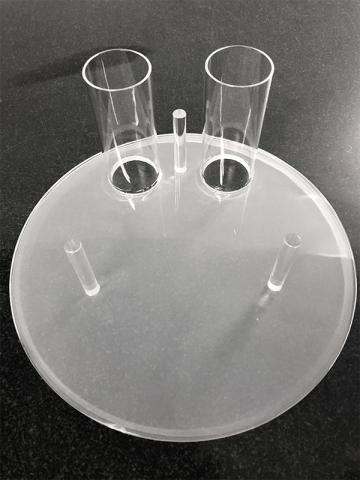

Quartz Bases

Name:

6-inch Quartz Base

Function & Application:

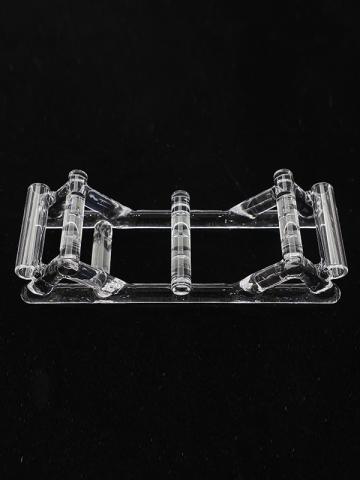

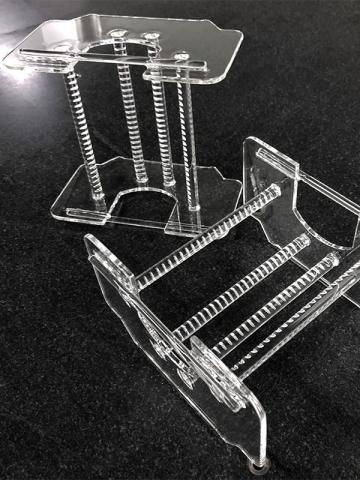

The quartz base supports a quartz boat on top and is used in wafer manufacturing processes such as diffusion, oxidation, CVD deposition, and annealing. It helps to distribute gas flow evenly, ensuring stable gas exposure to silicon wafers inside the top quartz boat. This is a high-temperature process.

Performance Requirements:

High temperature resistance, corrosion resistance, excellent thermal stability, sandblasted surface, and low impurity content.

-

No.5177 Qianghua West Road, Dongqian Street, Nanxun District, Huzhou City, Zhejiang Province

-

+86-572-3032373

+86-572-3033016

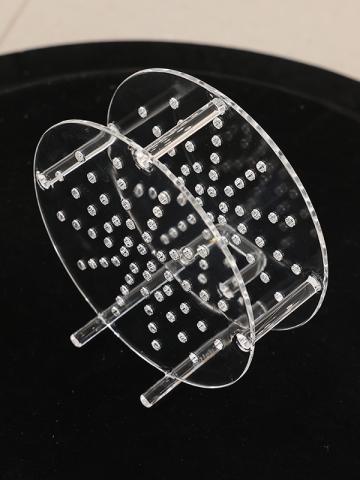

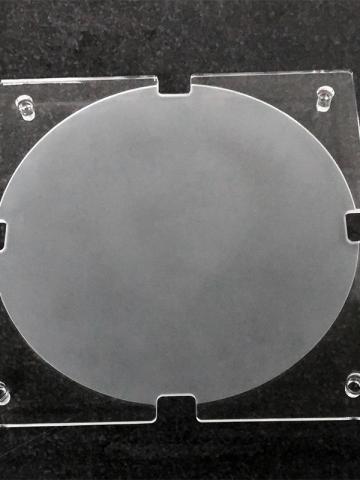

High Purity Quartz Pedestals serve as stable support structures designed to hold quartz boats securely during high-temperature semiconductor wafer fabrication processes such as diffusion, oxidation, CVD deposition, and annealing. Crafted from ultra-pure fused quartz, these pedestals provide excellent thermal stability and corrosion resistance, essential for maintaining process integrity.

Their precision-engineered sandblasted surfaces enhance gas flow distribution, ensuring uniform exposure of process gases to silicon wafers within the quartz boat. With low impurity content and robust construction, these pedestals minimize contamination risks and withstand repeated thermal cycling, making them indispensable components in advanced semiconductor manufacturing environments.

Why High Purity Quartz Pedestals are Critical in Semiconductor Furnaces

Why Purity Matters

In semiconductor processing, even microscopic contamination can cause wafer defects, leading to lower yields. High purity quartz pedestals:

1. Minimize contamination risks by avoiding impurities that could migrate to wafers.

2. Withstand high temperatures (up to 1200°C or more) without deformation.

3. Resist chemical attack from gases used during diffusion and oxidation.

Role in Furnace Performance

The performance of semiconductor furnaces relies heavily on uniform temperature distribution and stability. Quartz pedestals contribute to this by:

1. Supporting wafer carriers securely to prevent misalignment.

2. Maintaining dimensional stability under thermal cycling.

3. Enhancing wafer uniformity by ensuring consistent positioning during high-temperature processes.

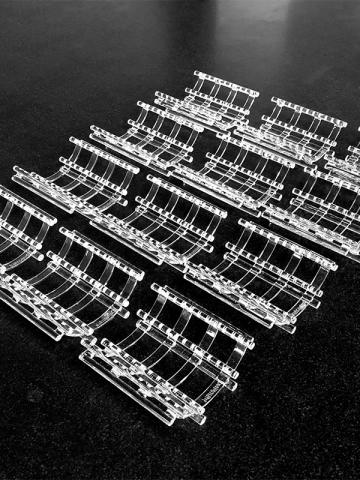

Reliability and Longevity

Because quartz pedestals are repeatedly exposed to extreme thermal and chemical environments, durability is a major concern. High-purity quartz extends service life, reduces maintenance costs, and helps fabs minimize downtime caused by part replacements.

High purity quartz pedestals may seem like a small part of semiconductor furnaces, but their role is fundamental. By ensuring cleanliness, stability, and reliability, they directly impact wafer quality and overall production yield. For fabs seeking consistent performance, investing in high-quality quartz pedestals is not just beneficial—it’s essential.