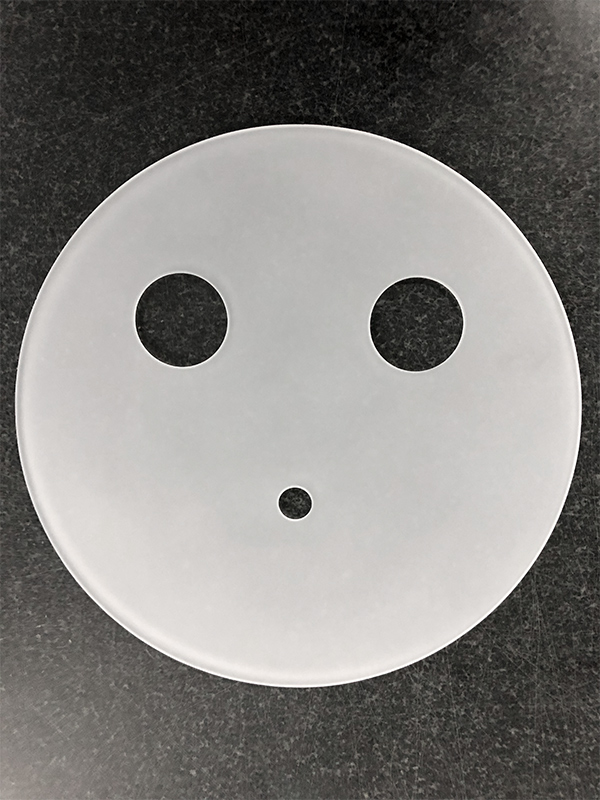

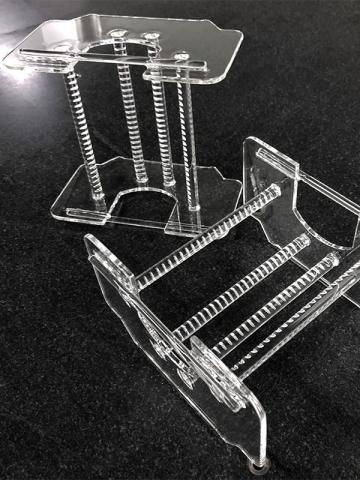

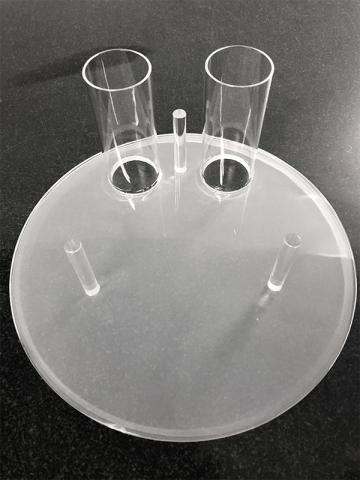

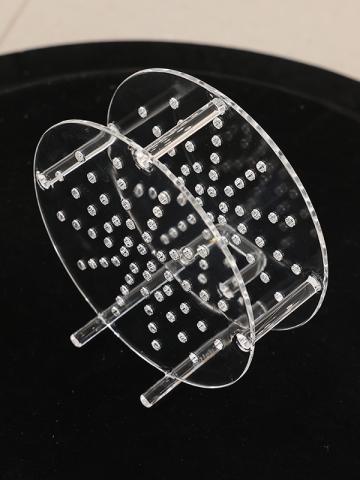

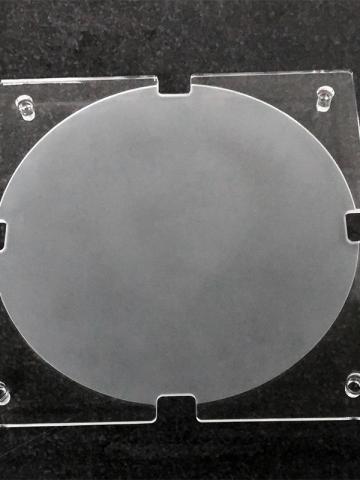

Baffle

Name:

6-inch Quartz Baffle

Function & Application:

It distributes heat more evenly by reflecting and diffusing thermal energy, effectively protecting wafers from direct radiation and localized overheating inside the high-temperature processing furnace. It is used in diffusion, oxidation, and CVD deposition processes in wafer manufacturing, which are high-temperature processes.

Performance Requirements:

High temperature resistance, corrosion resistance, excellent thermal stability, sandblasted surface treatment, and low impurity content.

-

No.5177 Qianghua West Road, Dongqian Street, Nanxun District, Huzhou City, Zhejiang Province

-

+86-572-3032373

+86-572-3033016

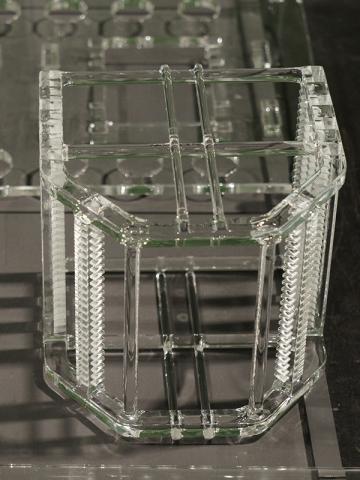

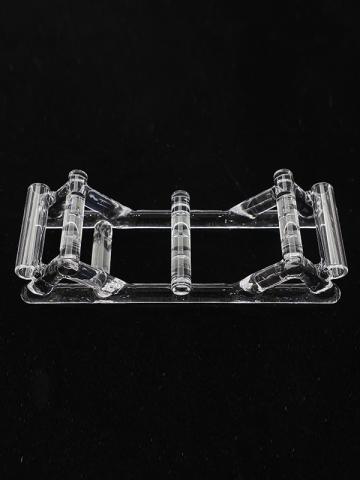

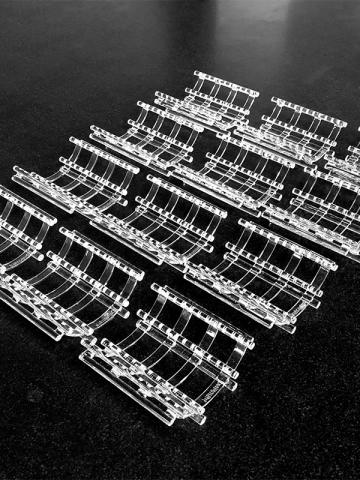

Thermal‑Shield Quartz Baffles are precision-engineered components designed to improve heat distribution and protect silicon wafers from direct radiation and localized overheating during high-temperature semiconductor processes such as diffusion, oxidation, and CVD deposition. By reflecting and diffusing thermal energy inside the furnace, these baffles ensure a more uniform temperature profile, reducing thermal stress and enhancing wafer quality.

Manufactured from high-purity fused quartz, the baffles feature a sandblasted surface treatment that minimizes particle generation and improves thermal performance. With excellent resistance to high temperatures and chemical corrosion, as well as low impurity levels, Thermal‑Shield Quartz Baffles provide durable, contamination-free operation in demanding cleanroom environments, contributing to improved process yields and device reliability.

Common Issues with Thermal‑Shield Quartz Baffles and Prevention

1. Thermal Stress Cracking

Repeated heating and cooling cycles can cause micro-cracks or fractures in quartz baffles.

Prevention: Use high-purity quartz with low thermal expansion and apply controlled ramp-up and cooldown rates in the furnace.

2. Warping or Deformation

Improper handling or installation may lead to warped baffles, disrupting gas flow and thermal uniformity.

Prevention: Ensure correct support and spacing; avoid excessive mechanical stress during installation.

3. Surface Contamination

Deposits from process gases or particles can accumulate, reducing thermal efficiency and causing contamination.

Prevention: Clean baffles regularly using non-abrasive methods and maintain strict cleanroom protocols.

4. Misalignment in Furnace

Incorrect positioning can cause uneven gas flow and localized overheating.

Prevention: Align baffles precisely with wafer boats and furnace guides during setup.

5. Chemical Erosion

Prolonged exposure to aggressive process gases may erode the quartz surface.

Prevention: Use corrosion-resistant, high-purity quartz and inspect components periodically.

By understanding these common issues and following preventive measures, manufacturers can maximize the performance and lifespan of thermal-shield quartz baffles, ensuring consistent wafer quality and improved yield.