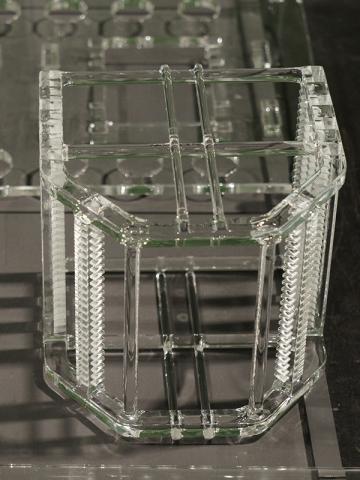

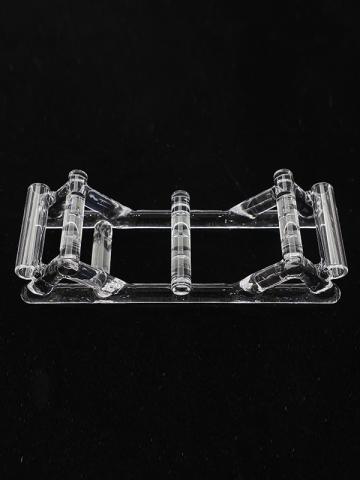

Boat Support

Name:

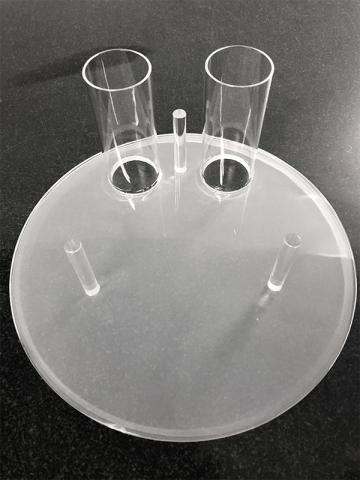

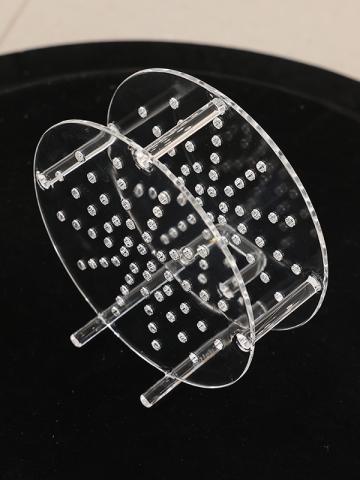

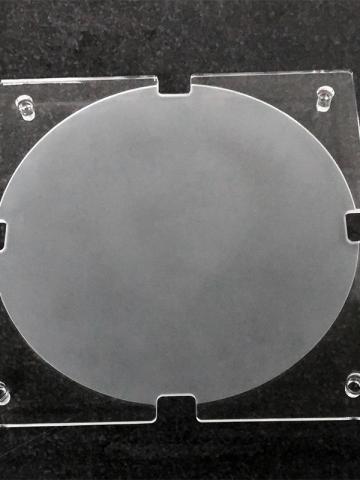

6-inch Quartz Boat Support

Function & Application:

The quartz boat is placed on the support/holder for transportation and processing, then loaded into the furnace tube for batch manufacturing. It is applied in diffusion, oxidation, and CVD deposition processes in wafer manufacturing, which are high-temperature processes.

Performance Requirements:

High temperature resistance, corrosion resistance, excellent thermal stability, high optical transparency, and low impurity content.

-

No.5177 Qianghua West Road, Dongqian Street, Nanxun District, Huzhou City, Zhejiang Province

-

+86-572-3032373

+86-572-3033016

The Quartz Boat Support is a high-purity fused quartz component engineered to securely hold quartz boats during transportation and high-temperature semiconductor wafer processing. Designed for use in diffusion, oxidation, and CVD deposition processes, this support ensures stable positioning of quartz boats inside furnace tubes during batch manufacturing.

Manufactured with excellent thermal stability and corrosion resistance, the support withstands extreme temperatures and harsh chemical environments without deformation. Its high optical transparency and low impurity content minimize contamination risks, maintaining cleanroom standards and supporting consistent wafer quality throughout the manufacturing cycle.

Selecting the Right Quartz Boat Support for Your Wafer Size

1. Understand Your Wafer Dimensions

The first step in choosing a quartz boat support is to know the diameter, thickness, and total number of wafers in a batch. Quartz supports are precision-engineered to hold wafers securely without bending or tilting. Using an incorrectly sized support can lead to wafer misalignment, uneven heating, or damage during processing.

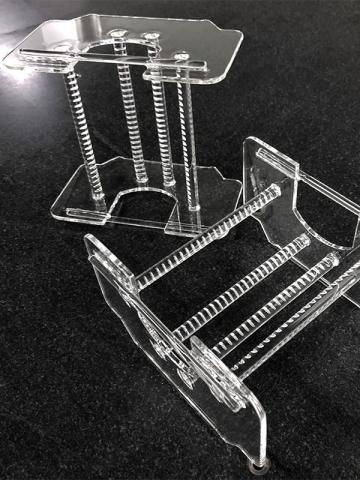

2. Match the Support to Your Furnace Type

Quartz boat supports vary depending on whether you are using vertical or horizontal furnaces. Vertical furnaces require supports that maintain consistent wafer spacing and ensure uniform gas flow, while horizontal furnace supports focus on even heat distribution and stable wafer alignment.

3. Consider Thermal Expansion and Material Purity

High-purity fused quartz is the standard for supports because it offers low thermal expansion, excellent thermal stability, and chemical inertness. Supports must maintain structural integrity under repeated high-temperature cycles to avoid cracking or wafer contamination.

4. Optimize Wafer Loading and Spacing

The design of the support slots or ledges affects wafer spacing and stability. Proper spacing improves gas flow and thermal uniformity, which directly impacts wafer yield and layer consistency during processes like diffusion, oxidation, and CVD deposition.

5. Customization Options

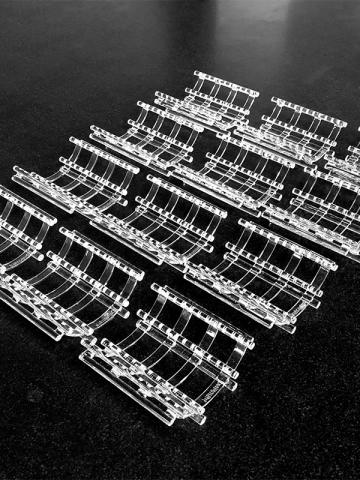

For specialized wafer sizes or batch processing requirements, custom quartz boat supports can be manufactured. These custom supports ensure perfect fit, maximize process efficiency, and reduce the risk of damage in advanced semiconductor applications.

Selecting the right quartz boat support ensures wafers are held securely, heated evenly, and processed without contamination. Properly matched supports enhance wafer yield, uniformity, and overall process reliability.