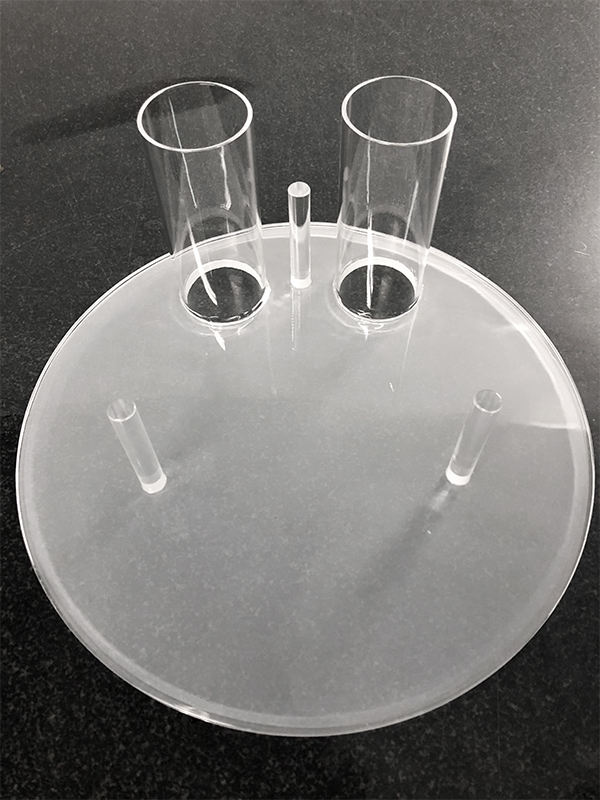

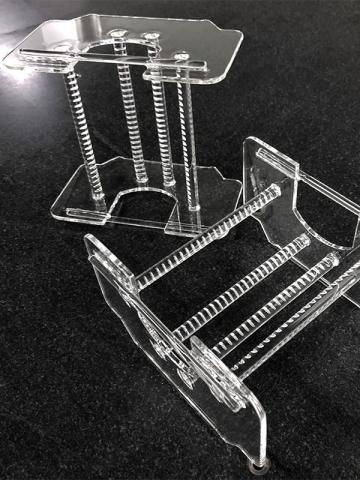

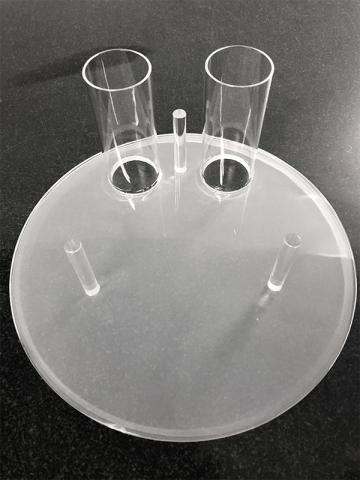

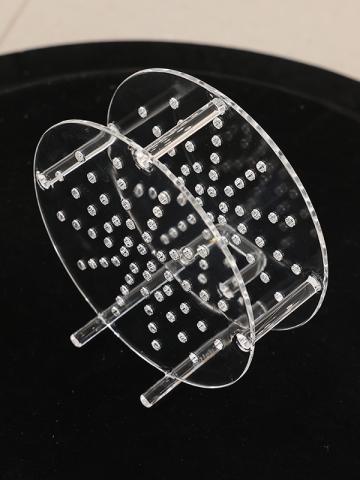

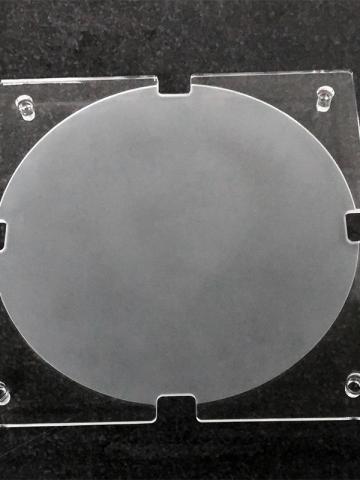

Baffle

Name:

6-inch Quartz Baffle for Horizontal Furnace

Function & Application:

It distributes heat more evenly by reflecting and diffusing thermal energy, effectively protecting wafers from direct radiation and localized overheating inside the high-temperature processing furnace. It is used in diffusion, oxidation, and CVD deposition processes in wafer manufacturing, which are high-temperature processes.

Performance Requirements:

High temperature resistance, corrosion resistance, excellent thermal stability, sandblasted surface treatment, and low impurity content.

-

No.5177 Qianghua West Road, Dongqian Street, Nanxun District, Huzhou City, Zhejiang Province

-

+86-572-3032373

+86-572-3033016

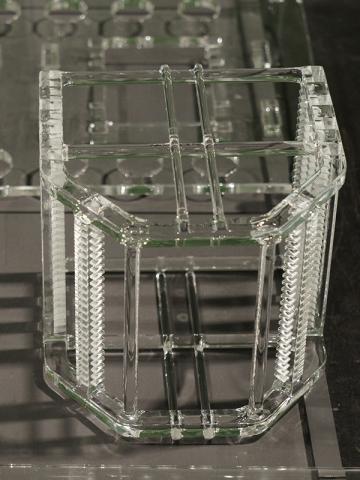

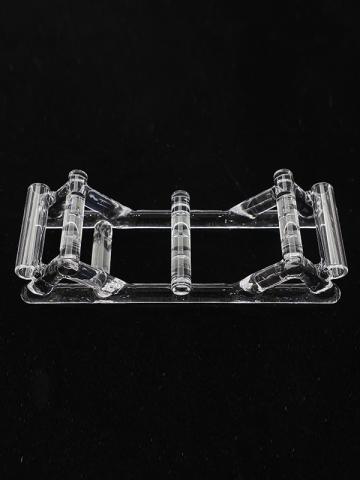

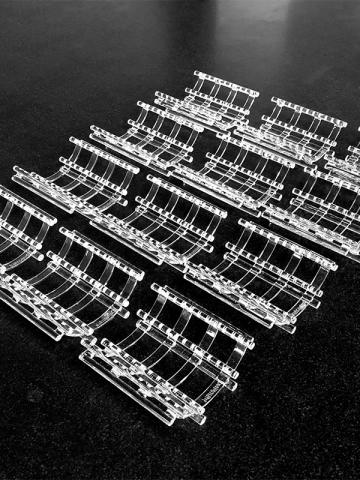

Quartz Baffles for Horizontal Furnace are specialized components designed to optimize thermal distribution and protect silicon wafers during high-temperature semiconductor processes such as diffusion, oxidation, and CVD deposition. Made from high-purity fused quartz, these baffles reflect and diffuse thermal energy within the furnace tube, helping to eliminate localized hotspots and ensuring uniform heat exposure across all wafers.

By acting as a thermal barrier, the baffles reduce direct radiation on wafer surfaces, thereby minimizing thermal stress and improving overall process consistency. The sandblasted surface treatment enhances thermal performance while minimizing particle generation. With excellent resistance to heat, chemical corrosion, and thermal shock, and with ultra-low impurity content, these quartz baffles are ideal for horizontal furnace setups in both production and R&D environments.

What is Horizontal Furnace in Semiconductor Industry?

A Horizontal Furnace in the semiconductor industry is a type of high-temperature processing equipment where wafers are loaded horizontally into a long, tubular furnace. It is widely used for thermal processes such as diffusion, oxidation, annealing, and chemical vapor deposition (CVD).

Key Characteristics

- Horizontal Loading: Wafers are placed on quartz boats or carriers and inserted horizontally into the furnace tube, allowing batch processing of multiple wafers simultaneously.

- Uniform Temperature Control: The furnace provides a controlled, stable temperature environment essential for precise dopant diffusion, oxide growth, or film deposition.

- Controlled Atmosphere: Gas flows (e.g., oxygen, nitrogen, dopant gases) are precisely regulated to ensure consistent process chemistry across all wafers.

- Batch Processing Efficiency: Enables high throughput by processing many wafers in one run, commonly used in semiconductor fabs for volume manufacturing.

Why Horizontal Furnaces Are Important

- They enable uniform thermal treatments critical for device performance.

- The horizontal design simplifies wafer loading/unloading and maintenance.

- Compatible with a variety of thermal processes needed in semiconductor fabrication.

Horizontal furnaces are essential equipment for performing reliable, high-volume thermal processes in semiconductor wafer manufacturing.