NEWS DETAIL

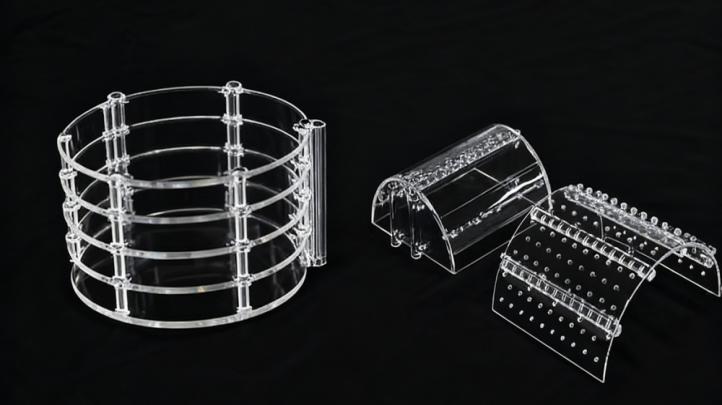

What is a Quartz Baffle Boat?

A quartz baffle boat is a precision-designed component made from high-purity quartz, commonly used in semiconductor manufacturing and diffusion processes. Its design features multiple baffles or partitions that help to control gas flow and ensure wafers are evenly exposed to process conditions. From my years of experience, the baffle structure is particularly valued when a stable and uniform environment is required for high-yield results. The quartz material is not only resistant to high temperatures but also offers exceptional chemical purity, reducing the risk of contamination during sensitive processes.

What is a Cage Boat?

A cage boat, on the other hand, is a quartz fixture that holds wafers in a “cage-like” structure. Unlike the baffle design, it focuses more on providing secure placement for wafers, allowing gases to flow more freely around them. In practice, cage boats are often chosen for processes where ease of loading and flexibility are more important than highly controlled gas distribution. From a handling perspective, many technicians appreciate that cage boats can be less cumbersome to use compared with more intricate baffle structures.

Design Differences: Structure and Material

Although both are made from high-purity quartz, their structural differences are significant. The quartz baffle boat includes multiple partitions that act as barriers to direct airflow, ensuring process gases reach wafers more evenly. Cage boats, by contrast, resemble open frames that provide stability without adding airflow restrictions. This design difference directly affects how wafers interact with the thermal and chemical environment inside the furnace.

Performance in Semiconductor Processes

In my experience, quartz baffle boats excel in applications where uniformity is critical, such as oxidation and diffusion processes. The controlled gas flow helps minimize defects across the wafer surface. Cage boats, while simpler, are more versatile in processes where uniformity requirements are less strict. They also allow easier handling during high-throughput manufacturing, making them practical for production lines where speed and efficiency matter.

Durability and Lifespan

Both designs are durable, but their longevity depends on the process conditions. Quartz baffle boats, due to their more complex structure, can sometimes be more prone to breakage if not handled carefully. Cage boats, with their simpler frame, are less fragile but may wear faster in high-temperature or corrosive environments. In both cases, regular inspection and proper cleaning are crucial for extending their lifespan.

Ease of Loading and Handling

One of the biggest practical differences buyers often ask about is ease of handling. Cage boats usually win in this area, as wafers can be loaded more quickly and the structure is easier to manipulate. Baffle boats, while more delicate and complex, require more careful handling but reward the effort with superior process control. For new technicians, cage boats can be less intimidating to work with, while experienced operators may prefer the precision offered by baffle boats.

Which is More Economical?

From a procurement standpoint, cage boats often come with a lower initial cost due to their simpler design. Quartz baffle boats, however, can deliver long-term savings if the process requires high uniformity and fewer defects, since better yield means lower overall production loss. Buyers should weigh not just the upfront price but also the total cost of ownership, including maintenance, replacement frequency, and process efficiency.

Which One Fits Your Application Better?

The choice between quartz baffle boats and cage boats ultimately depends on the process requirements. If uniform gas distribution and wafer consistency are critical, the baffle boat is the better choice. If flexibility, speed, and ease of handling are more important, then the cage boat may be the practical option. In many cases, facilities use both, selecting the right design depending on the step in their semiconductor production line.

Understanding the difference between quartz baffle boats and cage boats is essential for making informed purchasing decisions. While both serve the same fundamental purpose—holding wafers during processing—their design, performance, and handling characteristics make them suitable for different scenarios. With years of working alongside both, I have seen how the right choice can improve yield, reduce costs, and make daily operations smoother. Buyers should always consider their process priorities before deciding which design to adopt.