NEWS DETAIL

Why Proper Cleaning is Crucial for Industrial Quartz Parts

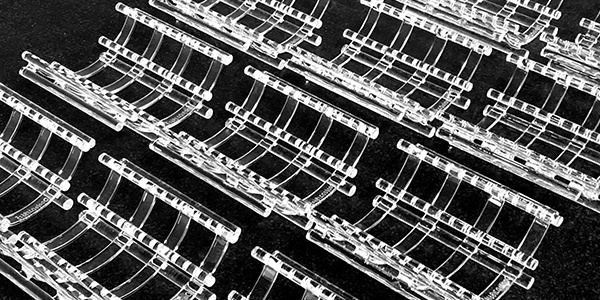

Industrial quartz components are essential in industries such as electronics, aerospace, and manufacturing. These parts are often used in precision instruments and high-temperature environments, making cleanliness and proper maintenance vital. Regular cleaning helps remove debris, prevent contamination, and ensure optimal functionality. Without proper care, quartz parts can experience reduced efficiency, surface degradation, or even malfunction in critical applications.

Step-by-Step Guide to Cleaning Industrial Quartz Components

Cleaning industrial quartz parts requires precision and attention to detail. Here’s a step-by-step guide to ensure thorough and safe cleaning:

Step 1: Gather Equipment – You'll need distilled water, a soft lint-free cloth, a non-abrasive brush, and a mild detergent (like isopropyl alcohol or specialized quartz cleaner).

Step 2: Rinse with Distilled Water – Begin by rinsing the quartz part with distilled water to remove any loose particles or debris.

Step 3: Apply Cleaning Solution – If necessary, use a mild detergent or specialized quartz cleaner to gently clean the surface with a soft cloth or brush. Ensure that the cleaner is designed for quartz to avoid damage.

Step 4: Gently Scrub – For stubborn particles or residues, use a soft brush or sponge to scrub the surface. Avoid using any abrasive materials that might scratch the quartz.

Step 5: Dry and Inspect – After cleaning, dry the part using a clean cloth and inspect it for any remaining contaminants or damage.

Best Cleaning Solutions for Industrial Quartz Parts

For industrial quartz components, the right cleaning solution is essential for maintaining their integrity.

Here are some options:

- Isopropyl Alcohol (IPA) – A common choice for cleaning quartz parts, isopropyl alcohol effectively dissolves oils and grease while being gentle on the surface.

- Distilled Water – Always use distilled water for rinsing or cleaning, as tap water contains minerals and impurities that could cause buildup or staining.

- Quartz-Specific Cleaners – For specialized components, there are cleaners formulated specifically for quartz, which can safely remove contamination without damaging the part.

Always avoid harsh chemicals, such as bleach or hydrochloric acid, as these can damage the surface and compromise the quartz’s structural integrity.

How to Avoid Scratches and Damage When Cleaning Quartz Parts

Quartz parts are durable, but they can still be damaged if cleaned improperly. To protect your components:

- Use Non-Abrasive Materials – Avoid abrasive pads, steel wool, or rough cloths that could scratch the surface. Use soft cloths, microfiber towels, or brushes.

- Be Gentle – Don’t apply excessive force when cleaning. Gentle, circular motions are best to avoid abrasion or surface damage.

- Avoid Dropping – Quartz parts, while tough, can be susceptible to breakage or chipping if dropped onto hard surfaces. Always handle with care and store in a secure, stable location.

Maintaining Industrial Quartz Parts for Longevity

Proper maintenance is key to ensuring industrial quartz parts function efficiently over time. Here are some tips:

- Regular Inspections – Periodically inspect quartz components for signs of wear or contamination. This is especially important in high-precision applications where even small impurities can affect performance.

- Avoid Direct Heat Exposure – Quartz can withstand high temperatures, but sudden temperature changes or exposure to extreme heat sources may cause cracks or thermal shock. Avoid placing quartz parts directly onto hot surfaces or subjecting them to rapid temperature shifts.

- Clean Immediately After Use – Contaminants such as chemicals, oils, or metal residues can affect the performance of quartz components. Clean parts immediately after use to prevent buildup.

Common Mistakes to Avoid When Caring for Industrial Quartz Parts

To ensure that industrial quartz parts remain in peak condition, avoid the following mistakes:

- Using Harsh Cleaning Chemicals – Harsh chemicals like ammonia or bleach can corrode or etch the surface of quartz. Always use cleaners specifically designed for quartz.

- Neglecting to Rinse Properly – Failing to rinse quartz parts thoroughly after cleaning can leave behind cleaning agents or residue, which can interfere with the part’s function.

- Improper Storage – Storing quartz parts in high-humidity environments or in contact with other materials that may scratch or damage the surface should be avoided. Store quartz parts in a dry, controlled environment to preserve their quality.