NEWS DETAIL

Understanding Quartz Boats and Tubes

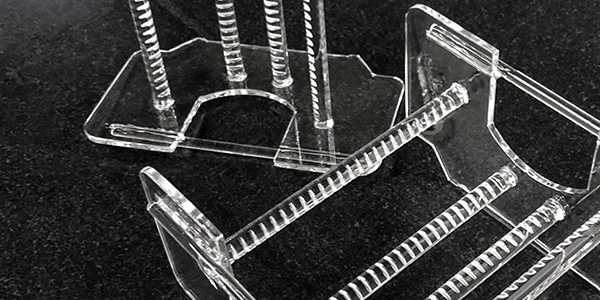

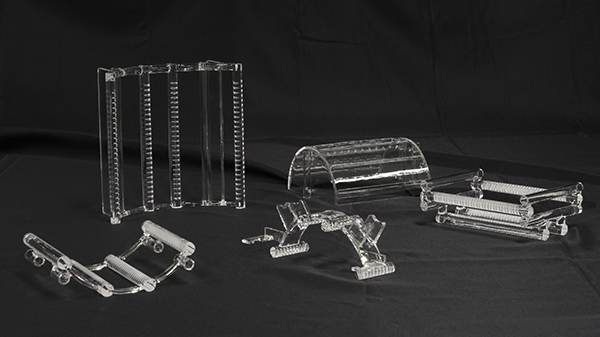

Quartz boats and quartz tubes are critical components in high-temperature processes such as chemical vapor deposition (CVD), semiconductor manufacturing, and advanced material synthesis. Quartz is chosen for these applications due to its excellent thermal stability, chemical resistance, and ability to withstand repeated heating cycles. Quartz boats are typically used to hold wafers or substrates inside a furnace, while quartz tubes serve as the reaction chamber or gas flow pathway. Understanding their function is essential because improper usage or maintenance can lead to premature failure, impacting product quality and increasing operational costs.

Common Causes of Wear and Damage

Despite their durability, quartz components are susceptible to wear and damage under certain conditions. Common causes include:

Thermal shock: Rapid heating or cooling can create cracks.

Chemical contamination: Residues from process gases or cleaning agents can corrode the quartz surface.

Mechanical stress: Mishandling during loading or unloading can cause chips or fractures.

Surface deposition: Build-up of materials on quartz surfaces can reduce efficiency and accelerate degradation.

Identifying these risks helps establish a proactive approach to extending lifespan.

Optimal Temperature and Handling Practices

Maintaining appropriate temperature control is crucial for preventing quartz damage. Recommendations include:

Gradual heating and cooling: Avoid sudden temperature changes; use controlled ramp-up and ramp-down cycles.

Temperature limits: Operate within the quartz manufacturer’s recommended thermal range to prevent structural stress.

Careful handling: Always use gloves or tongs when moving quartz boats and tubes. Avoid dropping or bumping components against hard surfaces.

Proper handling reduces the likelihood of thermal and mechanical stress, which are major contributors to premature failure.

Proper Cleaning Techniques for Quartz Components

Quartz cleaning is essential to remove chemical residues and surface deposits without compromising the integrity of the material. Effective techniques include:

Chemical cleaning: Use mild acids or alkaline solutions specifically recommended for quartz. Avoid strong hydrofluoric acid unless approved for specialized cleaning.

Ultrasonic cleaning: Can efficiently remove fine particles but should be applied carefully to prevent micro-cracks.

Rinsing and drying: Rinse thoroughly with deionized water and dry in a dust-free environment to prevent contamination.

Regular and proper cleaning helps maintain thermal performance, prevents contamination, and prolongs component lifespan.

Storage Tips to Prevent Contamination and Cracks

Proper storage further protects quartz boats and tubes when not in use. Best practices include:

Temperature-controlled storage: Avoid exposing quartz to extreme temperatures that could induce stress.

Protective packaging: Use cushioned containers or foam inserts to prevent mechanical damage.

Clean and dry environment: Store in a dust-free, low-humidity area to prevent contamination and moisture-related stress.

Segregation: Keep used and unused quartz components separately to avoid cross-contamination.

By combining careful storage with proper handling and cleaning, the service life of quartz boats and tubes can be significantly extended.

Extending the lifespan of quartz boats and tubes requires a comprehensive approach covering understanding their function, identifying potential damage sources, controlling operational temperatures, performing proper cleaning, and implementing careful storage. Adhering to these practices ensures consistent process quality, reduces replacement costs, and enhances operational efficiency in high-temperature manufacturing environments.