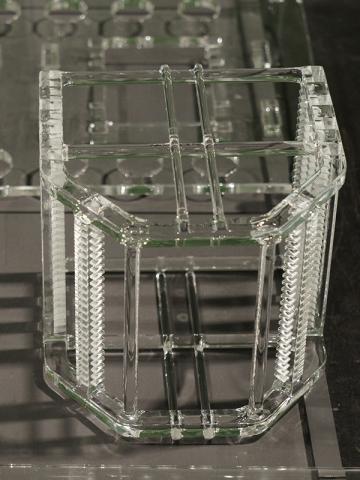

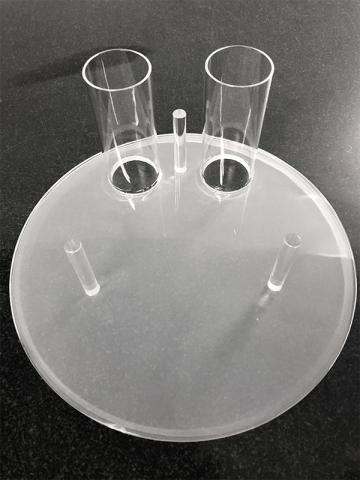

Baffle Boat

Name:

6-inch Quartz Baffle

Function & Application:

Quartz baffles play a critical role in stabilizing gas flow and temperature during high-temperature wafer processing. They are used in diffusion, oxidation, and CVD deposition processes to disperse gas flow evenly, ensuring that silicon wafers inside the quartz boat receive a uniform and stable flow.

Performance Requirements:

High temperature resistance, corrosion resistance, excellent thermal stability, sandblasted surface, and low impurity content.

-

No.5177 Qianghua West Road, Dongqian Street, Nanxun District, Huzhou City, Zhejiang Province

-

+86-572-3032373

+86-572-3033016

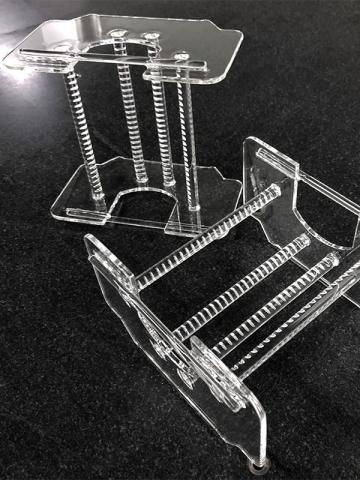

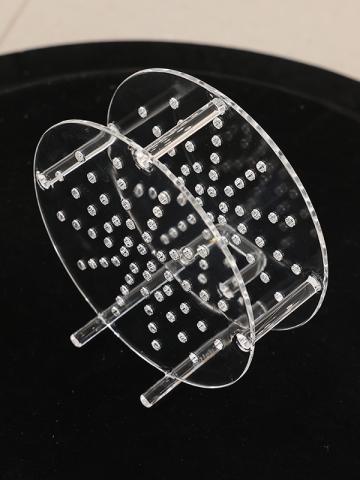

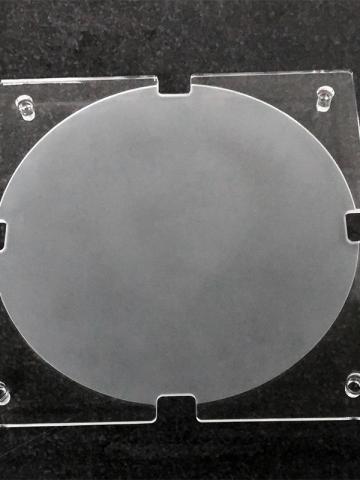

The quartz baffle boat is a high-purity quartz solution designed to enhance gas flow control and thermal consistency during high-temperature semiconductor processes such as diffusion, oxidation, and CVD. By integrating precision-formed baffle structures, it ensures uniform gas dispersion throughout the quartz boat, enabling each silicon wafer to receive stable and equal exposure to process gases.

This contributes significantly to thin-film uniformity and reduces wafer-to-wafer variations, ultimately improving device yield. Its robust construction offers outstanding high-temperature resistance, corrosion resistance, and thermal stability, while the sandblasted surface helps minimize particle generation. Each unit is manufactured with low impurity content and tight dimensional tolerances, making it a reliable choice for demanding cleanroom environments and automated wafer handling systems.

Quartz Baffle Boats: Enhancing in Semiconductor Furnaces

In semiconductor manufacturing, achieving uniform processing conditions is critical for high device yield and performance. Quartz baffle boats are specialized wafer carriers designed to improve gas flow distribution inside high-temperature processing furnaces such as diffusion or chemical vapor deposition (CVD) systems.

What Are Quartz Baffle Boats?

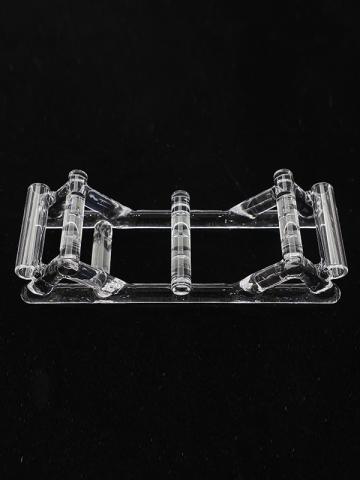

Quartz baffle boats are quartz wafer holders equipped with additional internal or external baffles—thin quartz plates or walls—integrated into the boat structure. These baffles act as flow restrictors or guides that direct process gases more evenly across the wafer surfaces.

Unlike standard quartz boats that simply hold wafers in vertical slots, baffle boats manage and optimize gas dynamics within the furnace tube to reduce boundary layer variations and improve wafer-to-wafer uniformity.

Key Functions of Quartz Baffle Boats

- Improved Gas Distribution: Baffles create controlled flow paths that prevent gas channeling or stagnation zones, ensuring each wafer receives consistent exposure to reactive gases.

- Thermal Uniformity: By stabilizing gas flow, quartz baffle boats help maintain uniform temperature distribution around all wafers.

- Reduced Particle Contamination: Uniform flow decreases localized hot spots and unwanted chemical reactions that can generate particles.

- Enhanced Process Control: Baffle design can be customized for specific process chemistries and furnace geometries, allowing fabs to fine-tune process parameters.

Design Features of Quartz Baffle Boats

- Baffle Placement and Size: Strategically placed baffles control how gas enters, circulates, and exits the wafer stack. Their size and thickness balance flow restriction with pressure drop.

- Material Purity: Made from high-purity synthetic quartz, baffles maintain chemical inertness and resist thermal shock during furnace cycles.

- Slot Geometry Compatibility: Baffle boats maintain standard wafer slot dimensions to ensure wafers remain securely held during processing.

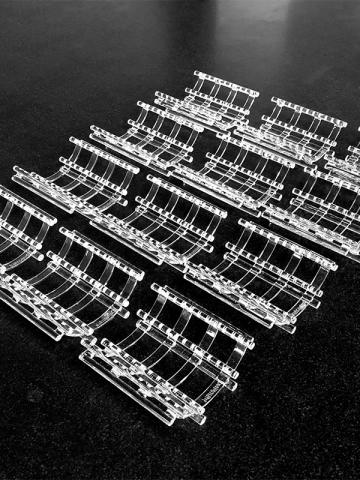

- Customizable Configurations: Depending on the furnace and process requirements, baffle boats can be customized with varying numbers, sizes, and placements of baffles.

Why Quartz Baffle Boats Matter

In processes like diffusion or CVD, gas flow uniformity directly impacts layer thickness consistency, dopant distribution, and defect rates. Quartz baffle boats enable fabs to:

- Achieve tighter process windows with less variation wafer-to-wafer.

- Improve device yield by reducing non-uniformities and particle contamination.

- Optimize throughput by enabling multi-wafer processing with consistent results.

Quartz baffle boats are vital for semiconductor fabs striving for superior uniformity and yield in vertical furnace processing. Their carefully engineered design improves gas flow and thermal conditions, making them a key tool in advanced wafer fabrication.