Quartz Boat

Name:

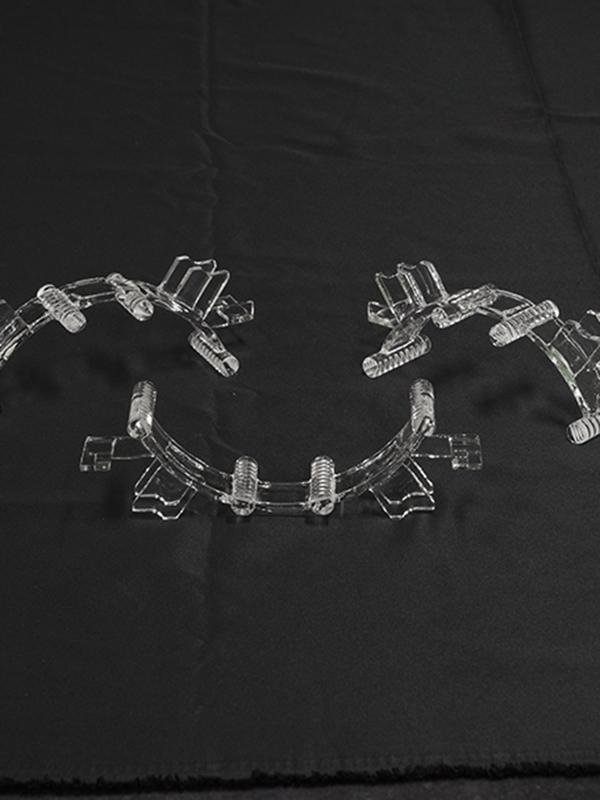

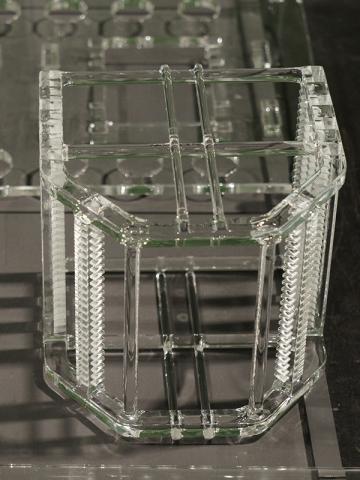

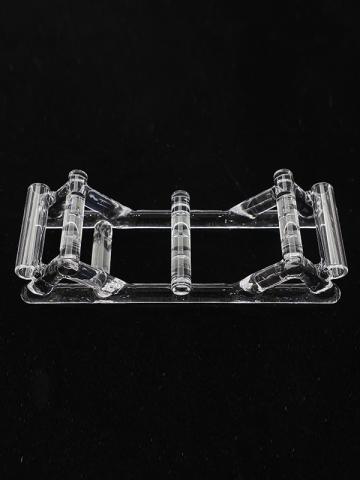

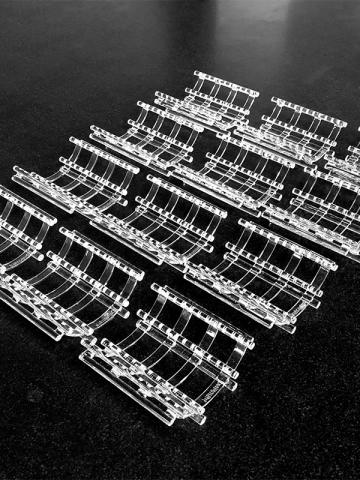

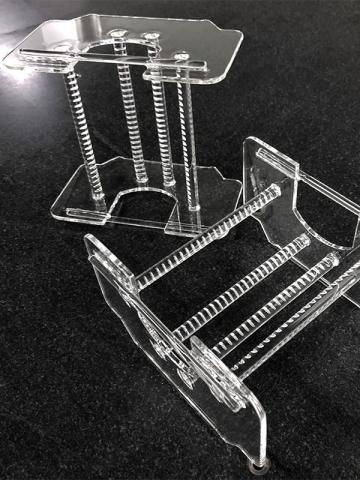

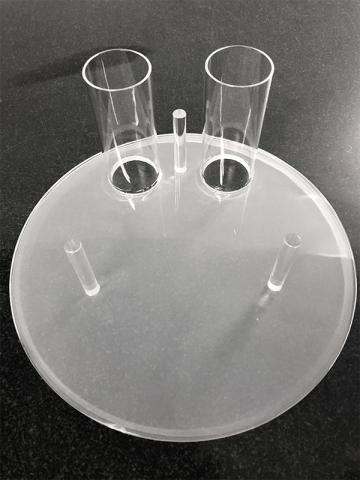

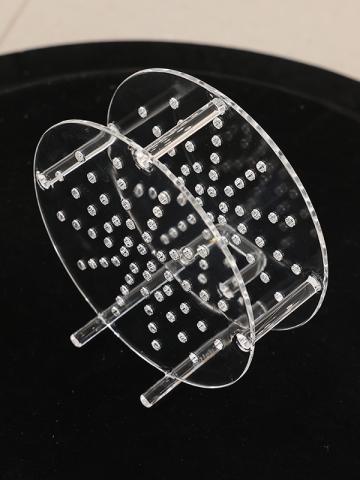

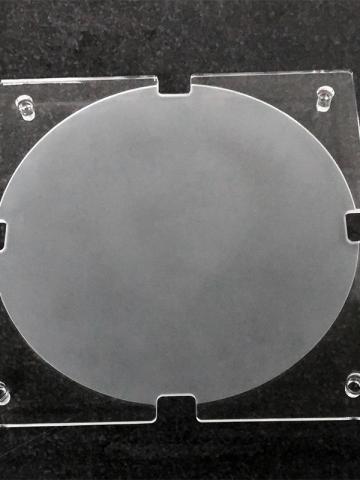

6-inch Quartz Wafer Boat

Function & Application:

The quartz wafer boat serves as a carrier for semiconductor wafers, which are loaded onto the boat and then placed into the furnace tube for batch processing. It is used in high-temperature processes such as diffusion, oxidation, and CVD deposition during wafer manufacturing.

Performance Requirements:

High temperature resistance, corrosion resistance, excellent thermal stability, high optical transparency, and low impurity content.

-

No.5177 Qianghua West Road, Dongqian Street, Nanxun District, Huzhou City, Zhejiang Province

-

+86-572-3032373

+86-572-3033016

The high purity quartz crystal wafer boat is a meticulously engineered carrier designed to securely hold silicon wafers during high-temperature semiconductor processes such as diffusion, oxidation, and CVD deposition. Constructed from ultra-high purity quartz (>99.99% SiO₂), it offers exceptional thermal stability, chemical inertness, and minimal impurity levels, ensuring contamination-free wafer processing.

This quartz wafer boat features a robust design that maintains dimensional accuracy and structural integrity through repeated thermal cycling. Its polished, smooth surfaces minimize particle generation and protect the delicate edges of wafers. Optimized for uniform wafer spacing and enhanced gas flow, it promotes consistent temperature distribution across all wafers, contributing to improved process yields and device performance. Ideal for demanding cleanroom environments and compatible with automated handling systems, this boat is essential for reliable semiconductor fabrication.

Common Issues with Quartz Wafer Boats and How to Avoid them

Quartz wafer boats are essential carriers in semiconductor manufacturing, holding wafers securely during high-temperature furnace processes. However, despite their robustness, quartz boats can encounter several common issues that affect production efficiency and wafer quality. Understanding these problems and knowing how to prevent them can save time, reduce costs, and improve yield.

1. Cracking and Fracture

Cause: Thermal shock from rapid temperature changes or mechanical stress during handling.

Prevention:

- Use controlled ramp rates during heating and cooling to minimize thermal stress.

- Handle boats carefully with proper tools and gloves to avoid impact damage.

- Choose high-quality quartz with good thermal shock resistance specifications.

2. Particle Generation

Cause: Surface degradation, micro-cracks, or contamination buildup leading to particle shedding.

Prevention:

- Maintain a smooth, polished surface finish during manufacturing.

- Implement regular and proper cleaning protocols using recommended solvents and methods.

- Inspect boats routinely for signs of wear or damage and replace as needed.

3. Warping and Dimensional Changes

Cause: Prolonged exposure to high temperatures causing creep or uneven thermal expansion.

Prevention:

- Select quartz boats made from high purity, low expansion quartz materials.

- Limit furnace cycle times and avoid overheating beyond specified limits.

- Monitor and document boat dimensional changes periodically.

4. Contamination

Cause: Impurities in quartz material, improper cleaning, or environmental exposure.

Prevention:

- Source boats with verified material purity and CoA certification.

- Use cleanroom-compatible cleaning and handling procedures.

- Store boats in contamination-free environments when not in use.

5. Slot Damage and Misalignment

Cause: Improper wafer loading/unloading, tooling wear, or mechanical impact.

Prevention:

- Train operators on careful wafer handling techniques.

- Regularly inspect slots and tooling for wear and replace when necessary.

- Use ergonomic loading equipment to minimize mechanical stress.

Addressing common issues with quartz wafer boats through proper material selection, handling, cleaning, and monitoring is crucial to maintaining process stability and maximizing wafer yield. Proactive maintenance and supplier collaboration can greatly extend the service life of quartz boats and reduce unexpected downtime in semiconductor fabs.