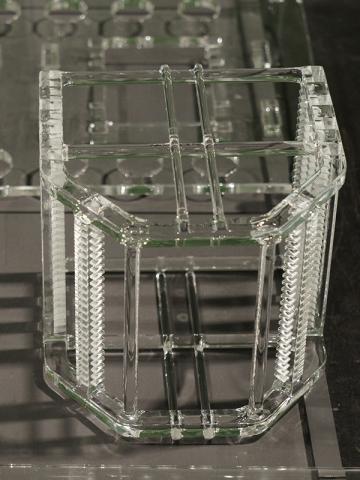

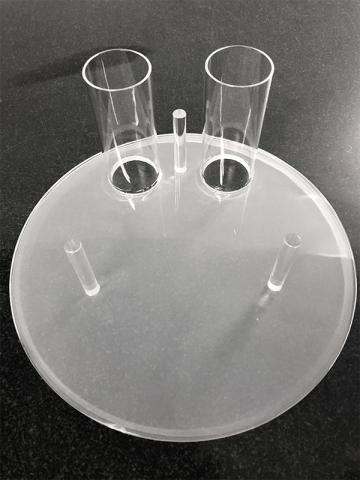

Quartz Boat

Name:

6-inch Quartz Boat

Function & Application:

The quartz boat is a carrier used to transport and process semiconductor wafers. Wafers are loaded onto the boat and placed into the furnace tube for batch processing. It is widely used in high-temperature wafer fabrication processes such as diffusion, oxidation, and CVD deposition.

Performance Requirements:

High temperature resistance, corrosion resistance, excellent thermal stability, high optical transparency, and low impurity content.

-

No.5177 Qianghua West Road, Dongqian Street, Nanxun District, Huzhou City, Zhejiang Province

-

+86-572-3032373

+86-572-3033016

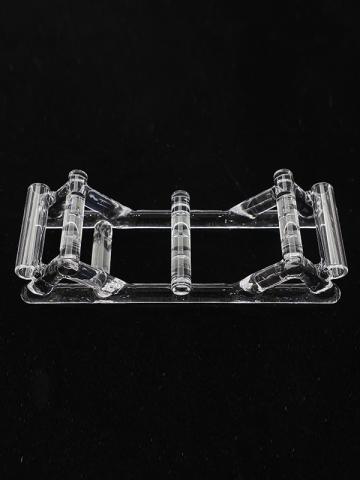

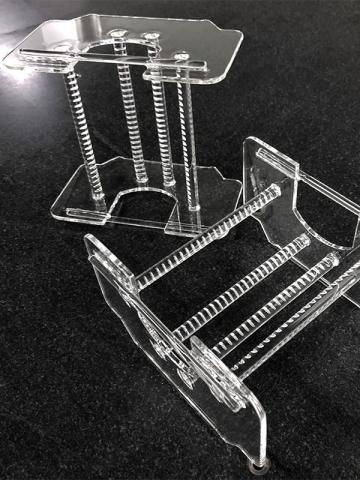

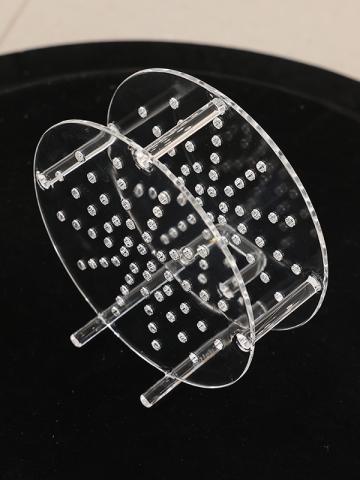

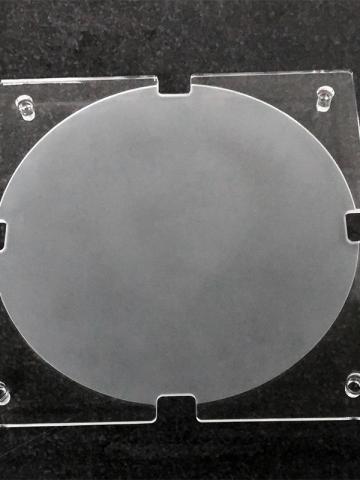

The quartz boat for diffusion of wafer processing is a high-precision carrier specifically designed to support silicon wafers during high-temperature diffusion steps in semiconductor manufacturing. Constructed from high-purity fused quartz, this boat delivers exceptional thermal stability, minimal thermal expansion, and superior chemical corrosion resistance, making it ideal for use in oxidizing and dopant-rich furnace environments.

Its engineered design optimizes gas flow and thermal uniformity within the furnace tube, ensuring even diffusion across all wafer surfaces for consistent dopant distribution and layer formation. The precisely machined slots securely hold wafers with accurate spacing and alignment, reducing the risk of wafer warpage and particle contamination. Robust and reliable, this quartz boat enables high-yield, repeatable diffusion processing critical to semiconductor device quality and performance.

Why High-Purity Quartz Boats are Crucial for Wafer Diffusion Processes

Wafer diffusion is a key step where dopants are introduced into silicon wafers at high temperatures to modify their electrical properties. The choice of equipment used during this process, particularly the quartz boat that holds and transports wafers inside the diffusion furnace, plays a critical role in ensuring process quality and yield. High-purity quartz boats have become the industry standard due to their unique properties that address the stringent demands of wafer diffusion.

1. Superior Thermal Stability and High-Temperature Resistance

Wafer diffusion typically occurs at temperatures ranging from 800°C to 1200°C. High-purity quartz boats can withstand these extreme conditions without deforming or cracking. Their low thermal expansion coefficient ensures dimensional stability during rapid thermal cycles, preventing wafer misalignment or damage. This stability is essential for maintaining uniform diffusion across all wafers.

2. Exceptional Chemical Inertness

The diffusion process involves reactive gases like oxygen, nitrogen, and dopant-containing species that can be highly corrosive. High-purity quartz boats resist chemical attack and do not release impurities into the furnace environment, preserving wafer surface integrity and preventing contamination that could impact device performance.

3. Minimal Contamination and Impurity Levels

Quartz boats made from ultra-high purity fused quartz (typically >99.99% SiO₂) have minimal metallic and particulate impurities. This purity reduces the risk of particle generation or contamination during processing, which is crucial for achieving high device yields and reliable semiconductor performance.

4. Optimized Gas Flow and Uniform Diffusion

The design of high-purity quartz boats, including precise slot dimensions and spacing, promotes even gas flow distribution around the wafers. This ensures that dopants diffuse uniformly into the silicon substrate, resulting in consistent electrical characteristics across the wafer batch.

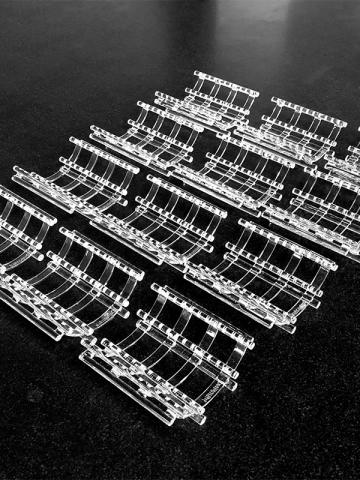

5. Durability and Long Service Life

Due to their excellent resistance to thermal shock and corrosion, high-purity quartz boats have a longer operational lifespan. This reduces downtime for equipment maintenance and replacement, improving production efficiency and lowering overall costs.