Quartz Boat

Name:

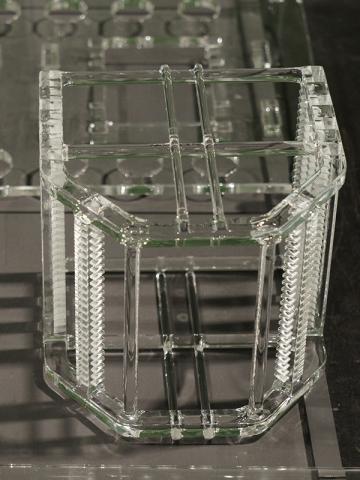

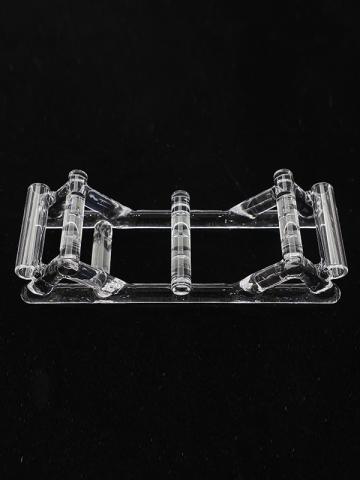

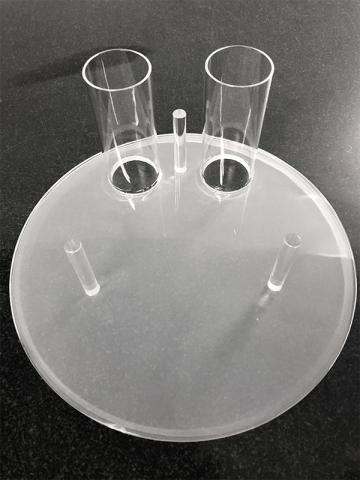

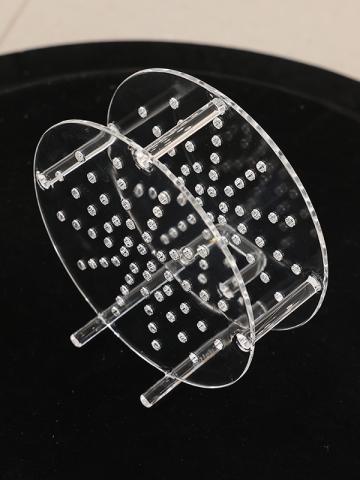

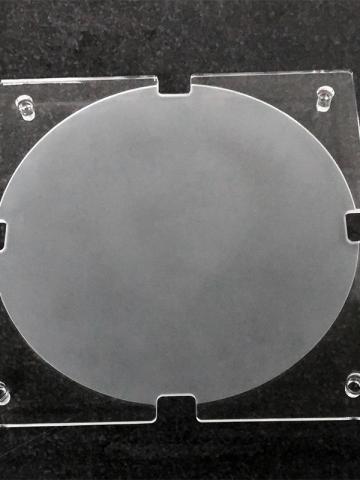

6-inch Curved Plate Quartz Boat

Function & Application:

The quartz boat is a carrier used to transport and process semiconductor wafers. Wafers are placed onto the quartz boat and then loaded into the furnace tube for batch processing. It is applied in high-temperature wafer fabrication processes such as diffusion, oxidation, and CVD deposition.

Performance Requirements:

High temperature resistance, corrosion resistance, excellent thermal stability, high optical transparency, and low impurity content.

-

No.5177 Qianghua West Road, Dongqian Street, Nanxun District, Huzhou City, Zhejiang Province

-

+86-572-3032373

+86-572-3033016

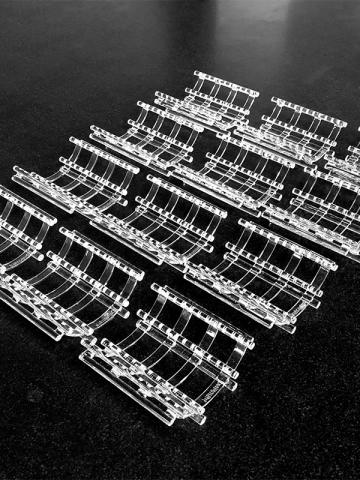

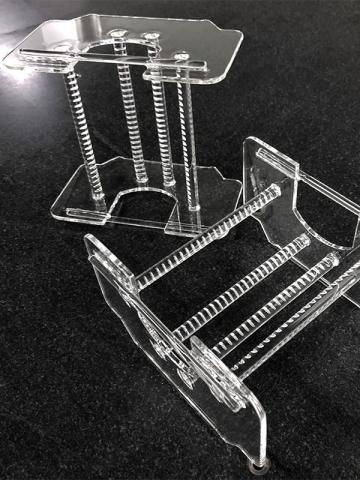

The High-Purity Curved Plate Quartz Boat is a precision-engineered wafer carrier designed for high-temperature semiconductor processes such as diffusion, oxidation, and CVD deposition. Made from ultra-clean fused quartz, this boat offers outstanding thermal stability, chemical resistance, and minimal impurity levels, making it ideal for cleanroom environments and contamination-sensitive applications.

Its bent plate design provides a stable and secure platform for wafer placement, allowing uniform heat transfer and controlled gas exposure during batch processing in furnace tubes. The structure ensures accurate wafer alignment and reduces mechanical stress, while the smooth, optically transparent quartz surface minimizes particle generation. Engineered for durability under repeated thermal cycling, this quartz boat supports consistent performance and process integrity in both production lines and laboratory testing environments.

Tips for Cleaning High-Purity Curved Plate Quartz Boat

High-purity quartz curved plate quartz boats are essential components in semiconductor manufacturing, providing reliable support for wafers during high-temperature processes like diffusion, oxidation, and CVD deposition. To maintain their performance and extend their service life, proper cleaning and maintenance are crucial. Here are effective tips for cleaning high-purity curved plate quartz boats:

1. Use Compatible Cleaning Agents

Avoid harsh chemicals that can damage the quartz surface or introduce impurities. Use diluted hydrofluoric acid (HF) solutions or specialized semiconductor-grade cleaning agents recommended by the manufacturer. Always follow safety protocols when handling acids.

2. Rinse Thoroughly with Deionized Water

After chemical cleaning, rinse the quartz boats thoroughly with high-purity deionized water to remove any residual chemicals. This step prevents contamination and potential damage during subsequent processing.

3. Employ Ultrasonic Cleaning

Ultrasonic baths can effectively remove particles and residues without scratching the quartz surface. Use low-power ultrasonic settings and semiconductor-grade cleaning solutions to protect the boat’s integrity.

4. Avoid Abrasive Materials

Never use abrasive brushes or pads that may scratch or damage the quartz surface. Scratches can become contamination sites and reduce thermal stability.

5. Dry Using Clean Air or Nitrogen

After cleaning, dry the quartz boats using filtered, clean air or nitrogen gas. This helps prevent water spots and particle deposition on the surface.

6. Regular Inspection and Maintenance

Inspect the quartz boats regularly for cracks, chips, or discoloration. Replace any damaged boats promptly to avoid wafer contamination or process failures.

7. Store Properly

Store cleaned curved plate quartz boats in clean, dust-free environments or sealed containers to protect them from contamination before reuse.