Quartz Boat

Name:

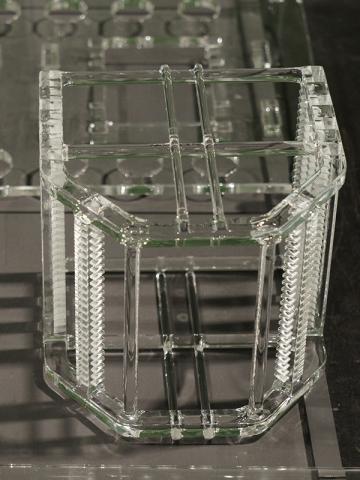

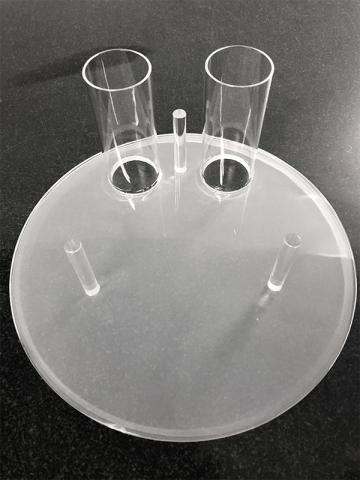

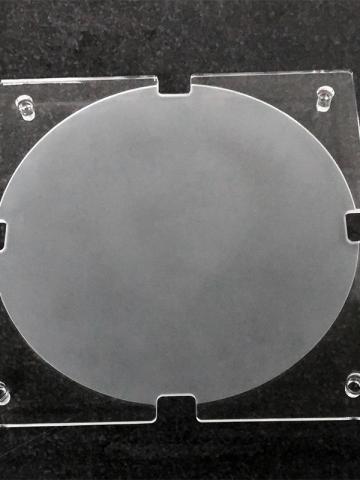

6-inch Quartz Tile Boat

Function & Application:

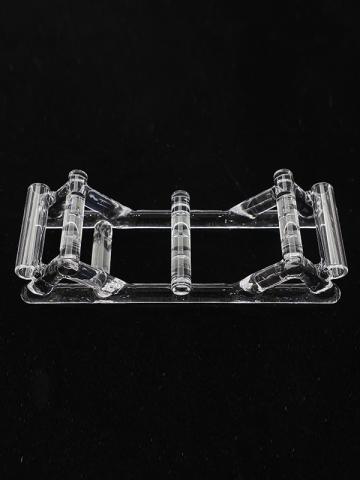

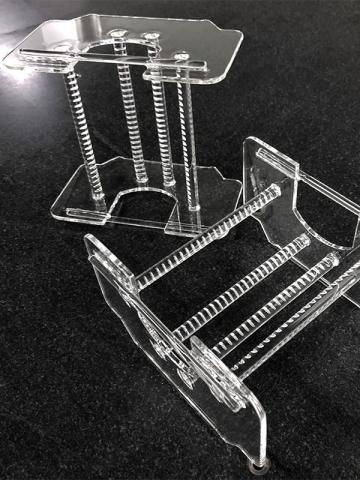

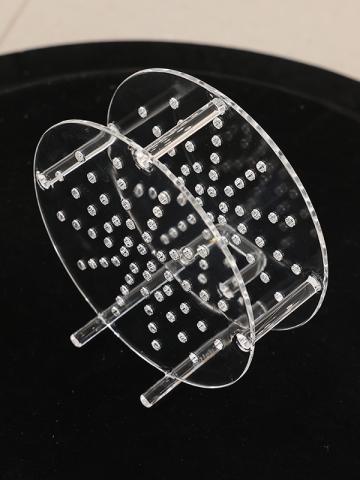

The arc-shaped curved plate features two rows of small holes in the middle, enabling its use in high-purity nitrogen, oxygen, or other inert gas environments. This design ensures uniform heating and full reaction with process gases without contaminating the silicon wafers. It is applied in high-temperature wafer fabrication processes such as diffusion, oxidation, and CVD deposition.

Performance Requirements:

High temperature resistance, corrosion resistance, excellent thermal stability, sandblasted surface, and low impurity content.

-

No.5177 Qianghua West Road, Dongqian Street, Nanxun District, Huzhou City, Zhejiang Province

-

+86-572-3032373

+86-572-3033016

The Good Quality Quartz Tile Boat is a high-performance wafer carrier engineered for use in high-temperature semiconductor fabrication processes such as diffusion, oxidation, and CVD deposition. Made from high-purity fused quartz, this boat features an arc-shaped curved plate with two central rows of precision-drilled holes. This design promotes uniform gas flow and consistent heating across all wafer surfaces, ensuring full and clean reaction with process gases in controlled atmospheres such as nitrogen, oxygen, or other inert gases.

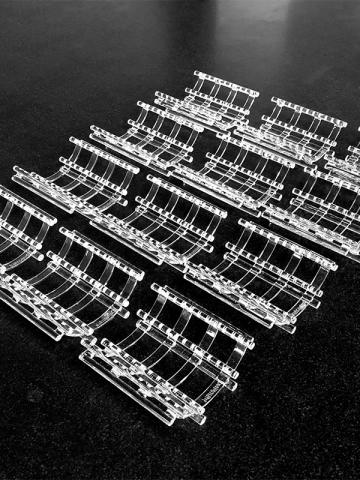

Its sandblasted surface reduces particle shedding while improving thermal stability and mechanical grip during processing. With excellent resistance to high temperatures and corrosive environments, along with low impurity levels, this tile boat ensures contamination-free performance and stable wafer positioning. It is ideal for both production and R&D environments where process consistency and material purity are critical.

What are Good Quality Quartz Tile Boats Used for?

Good Quality Quartz Tile Boats play a vital role in the semiconductor industry, especially during high-temperature wafer fabrication processes. These precision-engineered carriers are designed to hold silicon wafers securely while ensuring uniform heating and optimal gas flow within processing furnaces.

Applications of Quartz Tile Boats

Diffusion Processes

Quartz tile boats support wafers during diffusion, where dopants are introduced into the silicon substrate at high temperatures. Their design allows even gas distribution, helping achieve uniform dopant penetration across all wafers.

Oxidation Processes

During oxidation, silicon wafers form a thin oxide layer on their surface. The quartz tile boat’s material and perforated design ensure stable thermal conditions and gas flow, which are essential for consistent oxide thickness.

Chemical Vapor Deposition (CVD)

In CVD processes, thin films are deposited onto wafers through chemical reactions of gaseous precursors. Quartz tile boats facilitate even exposure of wafers to reactive gases, improving film uniformity and quality.

Why Choose Good Quality Quartz Tile Boats?

- High Purity Material: Made from high-purity fused quartz, these tile boats resist corrosion and minimize contamination, critical for maintaining wafer integrity.

- Uniform Heating: The arc-shaped curved plate with rows of small holes promotes uniform temperature distribution and gas flow.

- Durability: Excellent thermal stability and corrosion resistance allow for repeated use under harsh, high-temperature conditions.

- Compatibility: Designed for use in environments with high-purity nitrogen, oxygen, or inert gases to prevent wafer contamination.

Good Quality Quartz Tile Boats are essential tools in semiconductor wafer manufacturing, ensuring precise control of thermal and chemical environments. Their unique design and material properties contribute significantly to wafer quality, yield, and overall process reliability.