Cage Boat

Name:

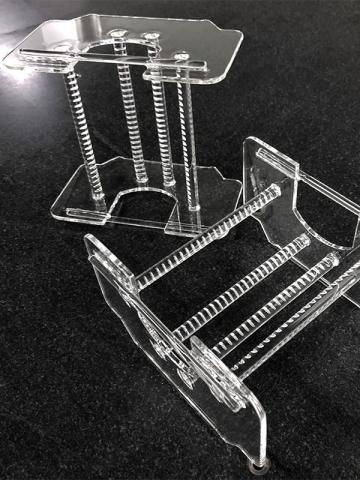

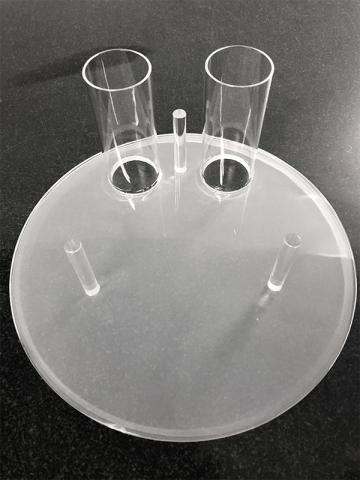

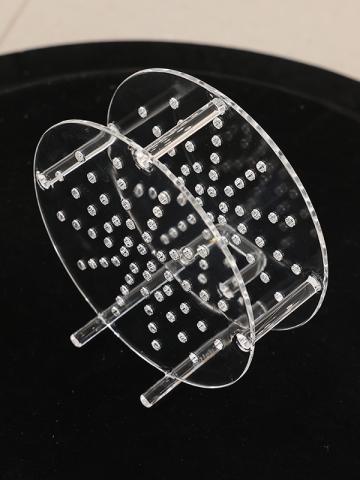

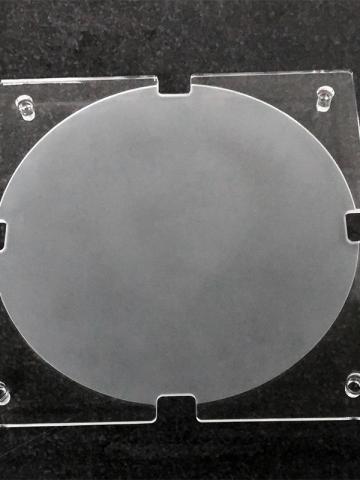

6-inch Quartz Cage Boat

Function & Application:

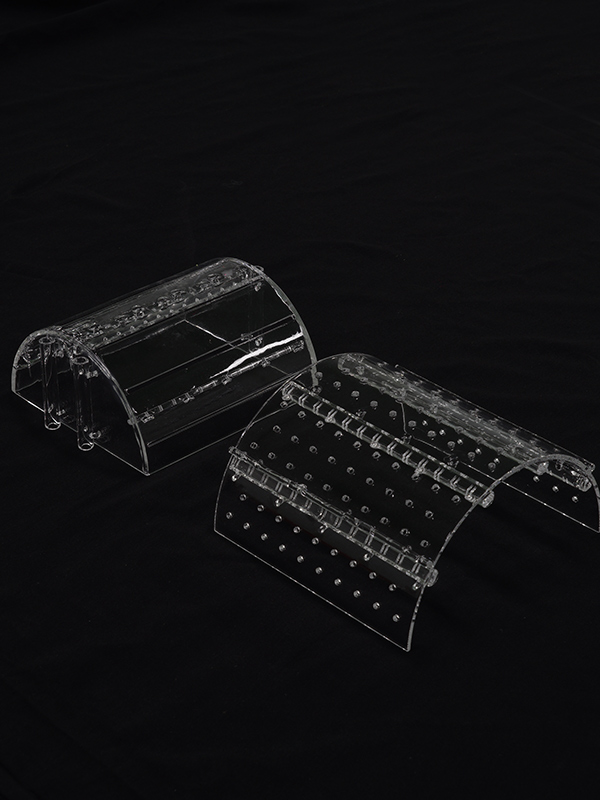

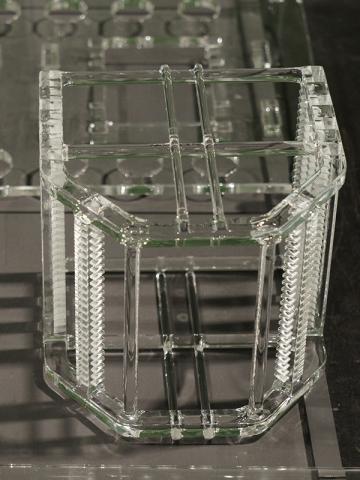

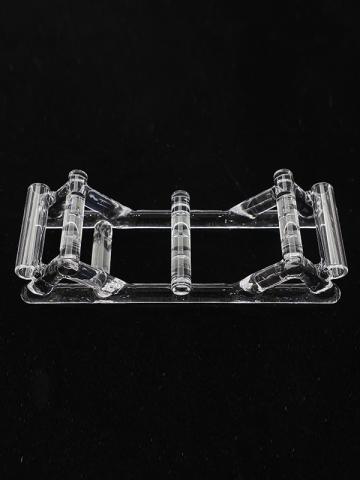

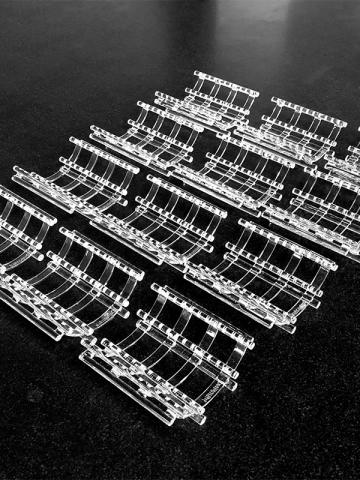

The arc-shaped curved plate is perforated with small holes, allowing the boat to be used in high-purity nitrogen, oxygen, or other inert gas environments. This design ensures uniform heating and full reaction with process gases without contaminating the silicon wafers. The 6-inch quartz cage boat is used together with a matching bottom and lid. It is typically applied in high-temperature wafer fabrication processes such as diffusion, oxidation, and CVD deposition.

Performance Requirements:

High temperature resistance, corrosion resistance, excellent thermal stability, high optical transparency, and low impurity content.

-

No.5177 Qianghua West Road, Dongqian Street, Nanxun District, Huzhou City, Zhejiang Province

-

+86-572-3032373

+86-572-3033016

The quartz cage boat is a precision-crafted high-purity quartz component designed to hold silicon wafers securely during high-temperature semiconductor processes such as diffusion, oxidation, and CVD deposition. Its arc-shaped curved plates are perforated with fine holes, enabling uniform heating and optimal gas exchange in inert or reactive atmospheres like nitrogen or oxygen—without introducing contaminants to the wafers.

This open cage structure enhances thermal uniformity and ensures full interaction between process gases and wafer surfaces, contributing to consistent processing results. Typically used in conjunction with a matched quartz base and lid, the cage boat features excellent thermal stability, corrosion resistance, and low impurity levels. Its high optical transparency supports visual inspection, and the design is compatible with automated handling systems in cleanroom environments. Custom configurations are available to meet specific furnace or process needs.

The Role of Surface Nanotexturing on Quartz Cage Boats

For semiconductor manufacturing, even the smallest details can significantly impact yield and quality. One emerging innovation enhancing quartz cage boats is surface nanotexturing — a precision modification technique that improves performance by altering the microscopic texture of quartz surfaces. Let’s explore how surface nanotexturing plays a critical role in advancing quartz cage boat technology and why it matters for fabs aiming to reduce contamination and boost wafer uniformity.

What is Surface Nanotexturing?

Surface nanotexturing involves engineering the quartz surface at the nanometer scale, creating controlled patterns or textures invisible to the naked eye. These nanotextures can modify surface properties such as adhesion, wettability, and particle retention.

Why Nanotexturing Matters for Quartz Cage Boats

Quartz cage boats support wafers during high-temperature processes in vertical furnaces. Contamination caused by particle shedding or micro-defects on quartz surfaces can lead to wafer defects and yield loss. Nanotexturing helps by:

- Reducing Particle Generation: Modified surface topography lowers particle adhesion and release during thermal cycling.

- Improving Gas Flow Dynamics: Nanotextured surfaces can influence local gas flow patterns, promoting uniform temperature distribution.

- Enhancing Surface Cleanability: Surfaces with engineered nanotextures resist contamination buildup and are easier to clean effectively.

- Increasing Mechanical Durability: Certain nanotextures can improve resistance to micro-cracks or wear under thermal stress.

Techniques Used for Nanotexturing Quartz Surfaces

- Laser Ablation: Uses focused lasers to etch nanoscale patterns precisely.

- Chemical Etching: Employs controlled chemical reactions to create surface features.

- Plasma Treatment: Modifies surface energy and roughness at the nanoscale.

Each method offers different advantages depending on desired texture characteristics and production scalability.

Impact on Wafer Yield and Process Stability

By minimizing particulate contamination and improving thermal uniformity, nanotextured quartz cage boats contribute to:

- Lower defect densities on wafers

- Higher process repeatability

- Reduced downtime for cleaning and maintenance

These benefits translate into significant cost savings and productivity gains in semiconductor fabs.

Considerations for Purchasing Nanotextured Quartz Cage Boats

- Verification of Nanotexture Quality: Ensure suppliers provide data on texture uniformity and durability.

- Compatibility with Cleaning Processes: Confirm that nanotextures withstand your fab’s cleaning chemicals and methods.

- Cost vs Benefit: Assess ROI considering longer cage lifetime and reduced yield loss.

- Customization Options: Work with suppliers to tailor nanotexturing for your specific furnace and wafer sizes.

Surface nanotexturing represents a cutting-edge advancement in quartz cage boat technology, directly addressing contamination and uniformity challenges in semiconductor processing. Incorporating nanotextured quartz cage boats into your production line can elevate yield, reduce defects, and extend component life—critical factors for competitive, high-volume fabs.