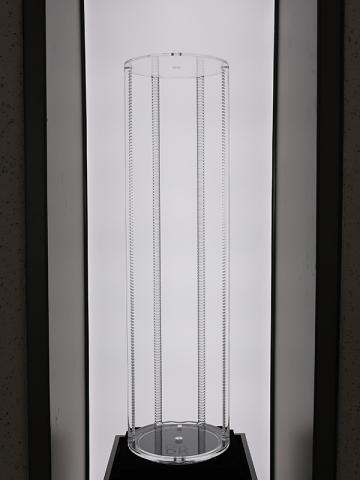

Chamber

Name:

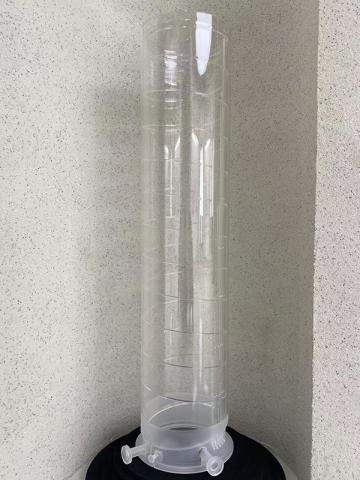

8-inch Quartz Chamber

Function & Application:

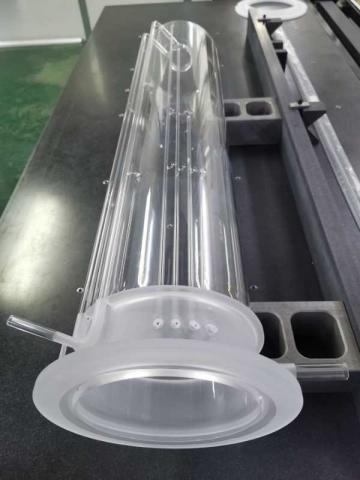

The quartz chamber serves dual functions of safe ignition and flame monitoring in high-temperature semiconductor manufacturing processes. It safely ignites process gases, continuously monitors the flame, and maintains process stability. It is applied in oxidation, CVD deposition, and furnace tube cleaning processes in wafer manufacturing, which are high-temperature processes.

Performance Requirements:

High temperature resistance, corrosion resistance, and low impurity content.

-

No.5177 Qianghua West Road, Dongqian Street, Nanxun District, Huzhou City, Zhejiang Province

-

+86-572-3032373

+86-572-3033016

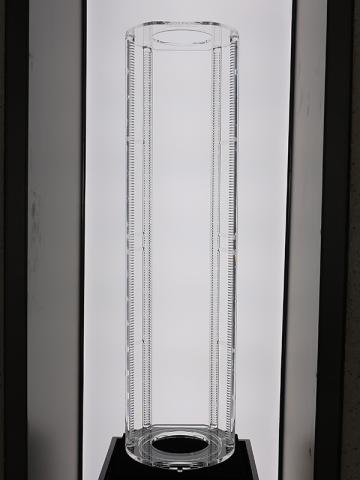

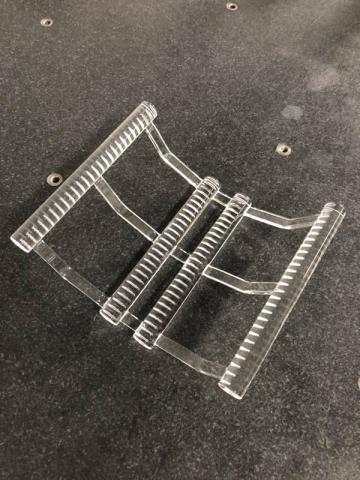

The quartz chamber serves as a critical enclosure for high-purity, high-temperature semiconductor and photovoltaic processing. Made from premium fused quartz, the chamber offers excellent thermal shock resistance, chemical inertness, and optical transparency, ensuring a contamination-free environment during processes like chemical vapor deposition (CVD), oxidation, and diffusion.

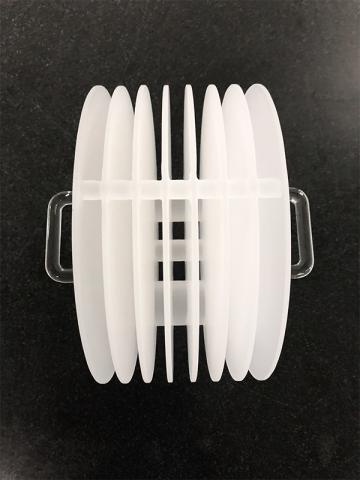

Designed to accommodate 200 mm wafers, the chamber provides uniform temperature and gas distribution, essential for achieving consistent process results and high device yields. Its precision-engineered construction withstands rigorous thermal cycling while maintaining structural integrity and minimizing particle generation.

Quartz Chambers for Plasma Etching: Ensuring Process Purity

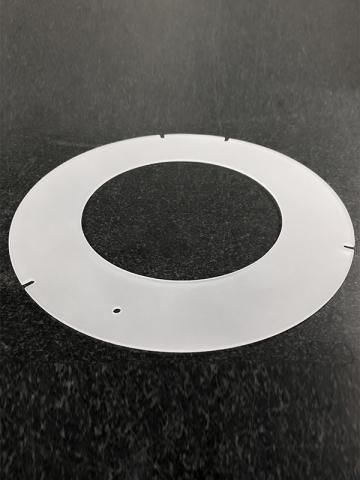

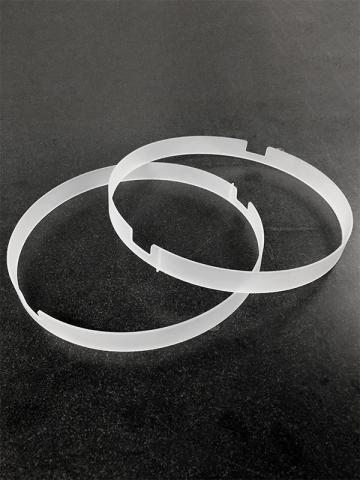

Quartz chambers play a vital role in plasma etching systems, providing a chemically inert and thermally stable environment essential for high-precision semiconductor processing. Constructed from high-purity fused quartz, these chambers resist corrosion from reactive plasma gases, preventing contamination and ensuring long-term durability under high-temperature conditions.

The smooth, low-particulate surfaces of quartz chambers minimize particle generation, which is critical for maintaining uniform etching across wafers. Proper gas flow design within the chamber enhances process consistency and helps achieve uniform material removal, critical in advanced IC fabrication.

Regular maintenance, including cleaning and inspection, ensures that the chamber maintains optimal performance over repeated etching cycles. Custom quartz chamber designs are also available to meet specific furnace and process requirements, providing semiconductor fabs with flexibility while maximizing wafer yield and process repeatability.