Quartz Boat

Name:

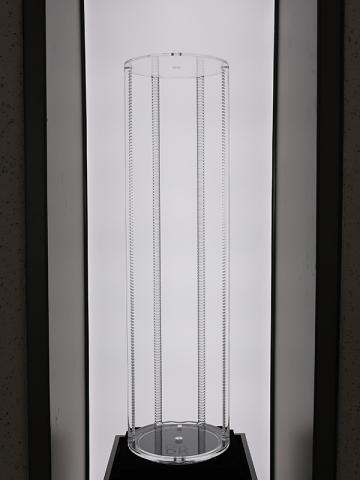

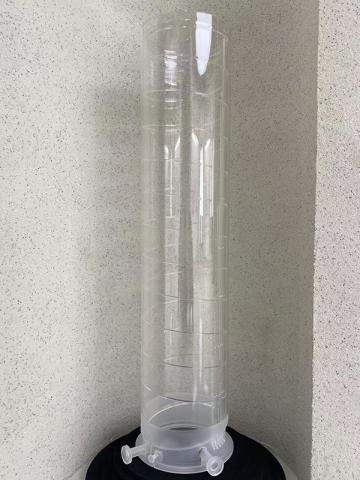

8-inch Vertical Furnace Quartz Wafer Boat

Function & Application:

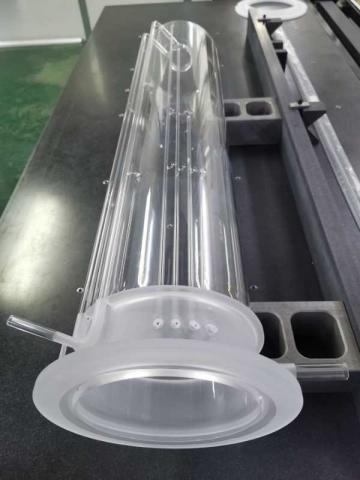

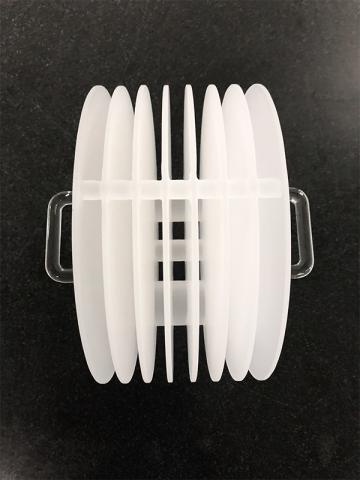

The vertical quartz boat is placed vertically inside the quartz tube and serves as a carrier for wafer transport, handling, and processing. Wafers are placed onto the quartz boat and then loaded into the furnace tube for batch manufacturing. It is used in diffusion, oxidation, and CVD deposition processes in wafer manufacturing, which are high-temperature processes.

Performance Requirements:

High temperature resistance, corrosion resistance, excellent thermal stability, high optical transparency, and low impurity content.

-

No.5177 Qianghua West Road, Dongqian Street, Nanxun District, Huzhou City, Zhejiang Province

-

+86-572-3032373

+86-572-3033016

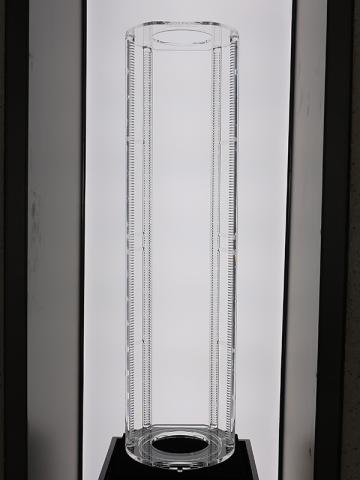

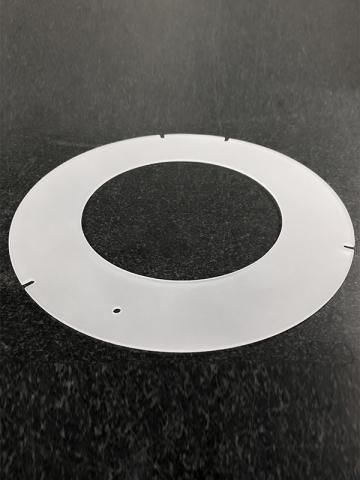

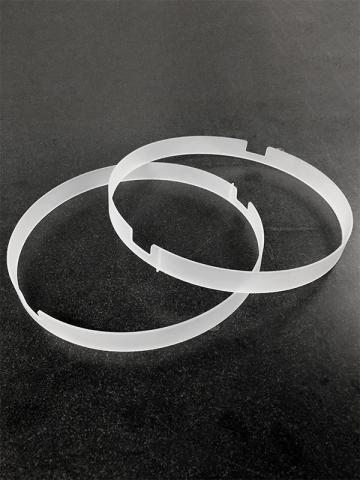

The clear quartz glass boat is designed for high-temperature semiconductor processing of 200 mm wafers, offering both structural precision and optical clarity. Fabricated from high-purity, transparent quartz glass, it provides excellent thermal stability, low thermal expansion, and strong resistance to corrosive gases and particle contamination.

The clear body allows for visual inspection of wafer placement and condition during loading and operation, supporting quality control without disrupting the process. Its optimized geometry ensures uniform wafer spacing, facilitating consistent gas flow and heat distribution within horizontal or vertical furnaces. Ideal for oxidation, diffusion, LPCVD, and annealing processes, this quartz glass boat combines material purity with process visibility—making it a reliable solution for advanced semiconductor fabrication environments.

Advantages of Using Clear Quartz Glass Boats

High Purity for Semiconductor Processes

Clear quartz glass boats are manufactured from high-purity quartz, ensuring minimal contamination during oxidation, diffusion, and epitaxy processes. This purity helps maintain wafer quality and device reliability.

Excellent Transparency

Their clear structure allows easy visual inspection of wafers during loading, processing, and unloading. Operators and automated systems can monitor wafer positioning more accurately, reducing handling errors.

Superior Thermal Properties

Quartz boats can withstand extreme furnace temperatures and rapid temperature fluctuations, offering strong resistance to thermal shock and ensuring long service life in harsh semiconductor environments.

Dimensional Stability and Precision

Clear quartz glass boats are precisely engineered to maintain consistent wafer spacing and alignment, which directly impacts process uniformity and wafer yield.

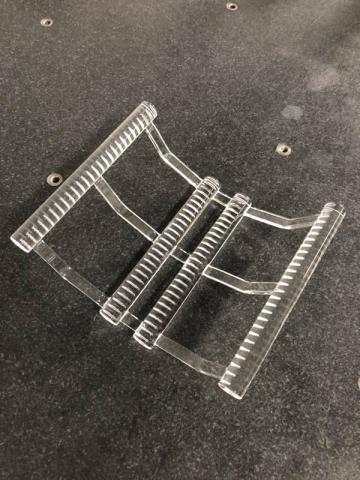

Compatibility with Automated Handling Systems

The smooth surface and precise geometry make them well-suited for robotic wafer loading and unloading, supporting advanced automation in semiconductor fabs.

Versatility Across Processes

Clear quartz boats can be used in oxidation, diffusion, LPCVD, and other furnace processes, making them a versatile choice for different semiconductor production lines.