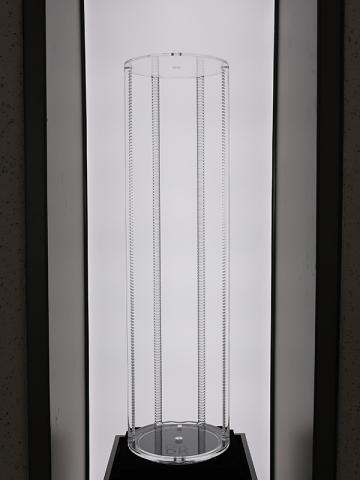

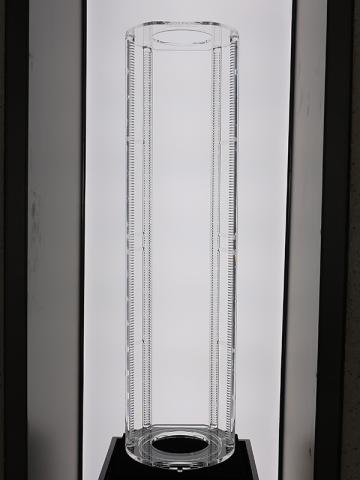

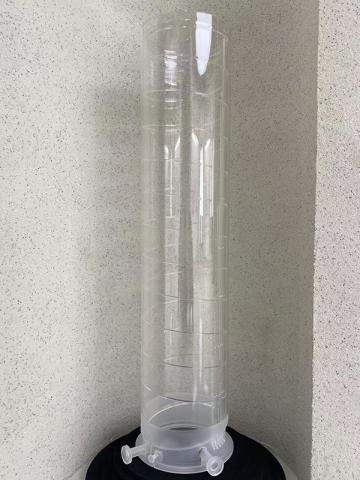

Quartz Cap

Name:

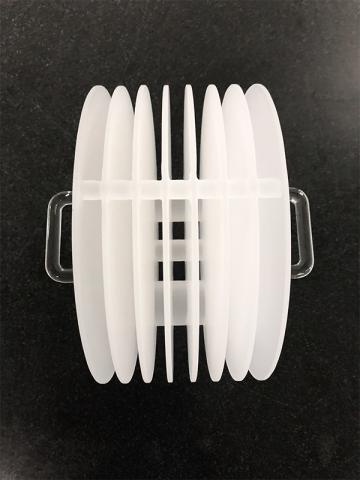

8-inch Quartz Cap (Quartz Inner Plug)

Function & Application:

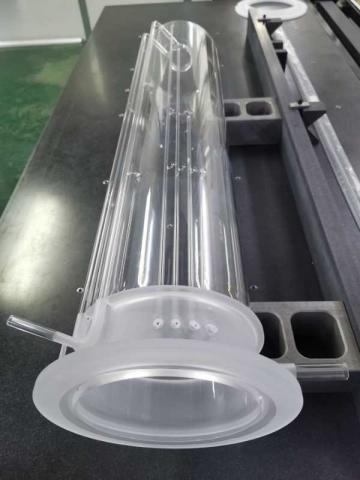

The quartz cap is a sealing component of the quartz tube that effectively controls the stability of furnace temperature during wafer processing and reduces heat radiation loss. It is applied in diffusion, oxidation, and CVD deposition processes in wafer manufacturing, which are high-temperature processes.

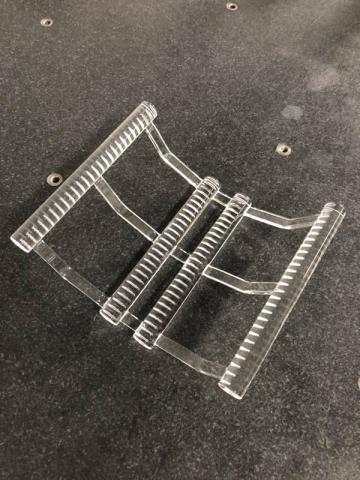

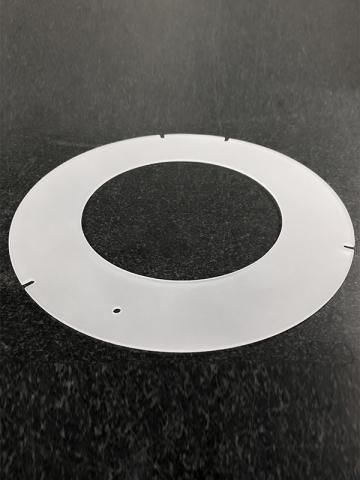

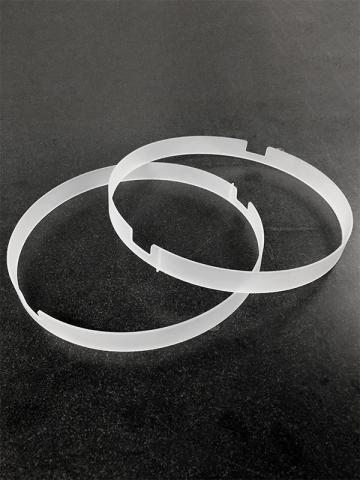

Performance Requirements:

High temperature resistance, corrosion resistance, excellent thermal stability, sandblasted surface treatment, and low impurity content.

-

No.5177 Qianghua West Road, Dongqian Street, Nanxun District, Huzhou City, Zhejiang Province

-

+86-572-3032373

+86-572-3033016

The quartz caps are precision-engineered components designed to seal and protect quartz tubes, reactors, and boats during high-temperature semiconductor and photovoltaic processes. Made from high-purity fused quartz, these caps provide excellent thermal stability, chemical resistance, and a tight, contamination-free seal.

Their durable construction withstands repeated thermal cycling, supporting consistent process performance and extended equipment lifespan. Compatible with standard 8 inch quartz process tubes and reactors, these caps are essential for maintaining cleanroom-grade conditions and process reliability in advanced wafer fabrication.

Selecting the Right Quartz Cap for Your Furnace System

Quartz caps are essential components in semiconductor furnace systems, protecting silicon wafers during high-temperature processes such as diffusion, oxidation, and CVD deposition. Made from high-purity fused quartz, they offer excellent thermal stability, chemical resistance, and low impurity content, ensuring that wafers remain uncontaminated throughout processing.

Choosing the correct quartz cap involves considering wafer size, furnace type, and process requirements. Properly designed caps improve heat distribution, maintain uniform wafer temperatures, and prevent defects caused by thermal gradients or contamination. Routine cleaning and careful handling further extend the service life of quartz caps, making them a reliable solution for semiconductor fabrication and research environments.