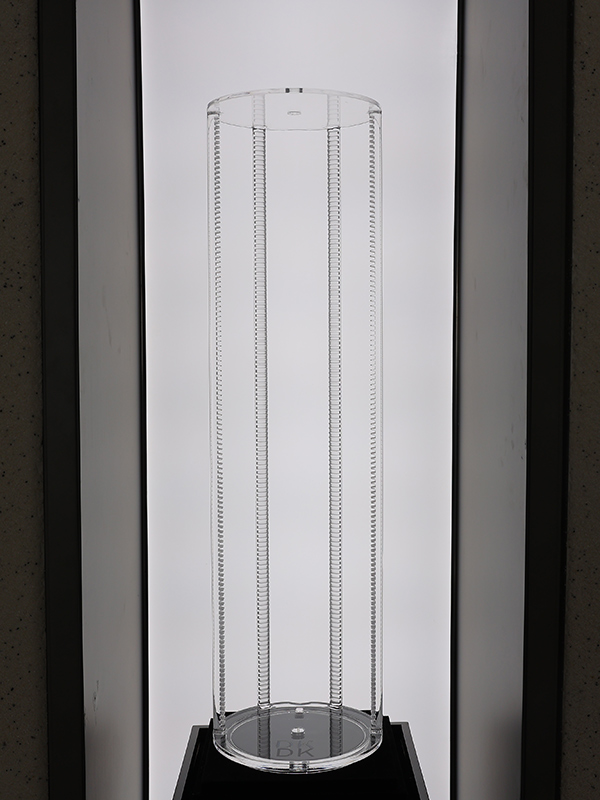

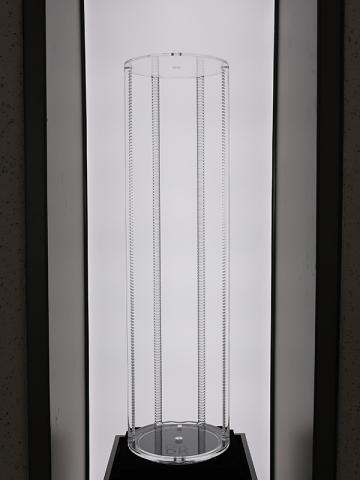

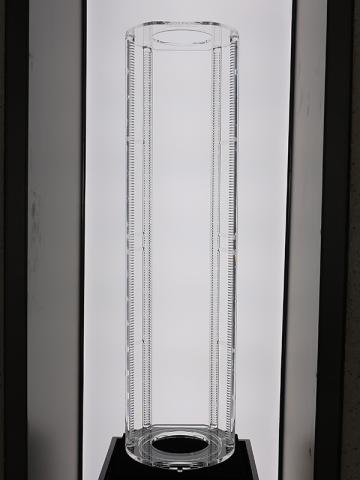

Quartz Boat

Name:

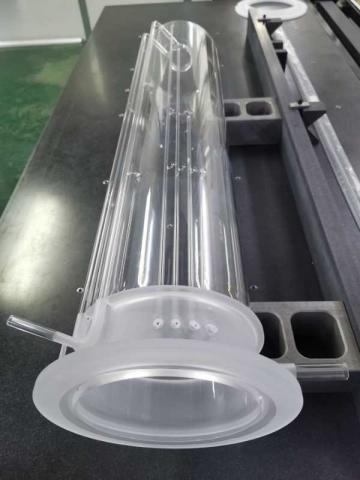

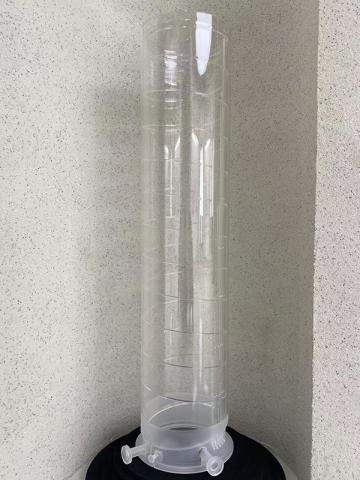

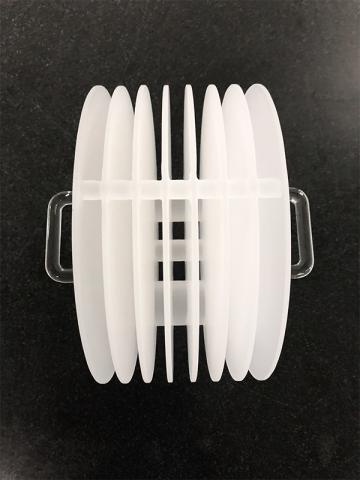

8-inch Vertical Furnace Quartz Wafer Boat

Function & Application:

The vertical quartz boat is positioned vertically inside the quartz tube and functions as a carrier for wafer transport, handling, and processing. Wafers are placed onto the quartz boat, which is then loaded into the furnace tube for batch manufacturing. It is used in diffusion, oxidation, and CVD deposition processes in wafer manufacturing, which are high-temperature processes.

Performance Requirements:

High temperature resistance, corrosion resistance, excellent thermal stability, high optical transparency, and low impurity content.

-

No.5177 Qianghua West Road, Dongqian Street, Nanxun District, Huzhou City, Zhejiang Province

-

+86-572-3032373

+86-572-3033016

The high purity quartz wafer boat is specifically engineered for secure and contamination-free handling of 200 mm wafers in high-temperature semiconductor manufacturing processes. Made from ultra-pure fused quartz, it exhibits outstanding thermal stability, low impurity levels, and excellent resistance to aggressive process gases.

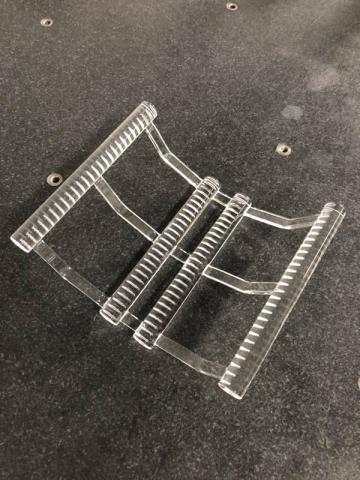

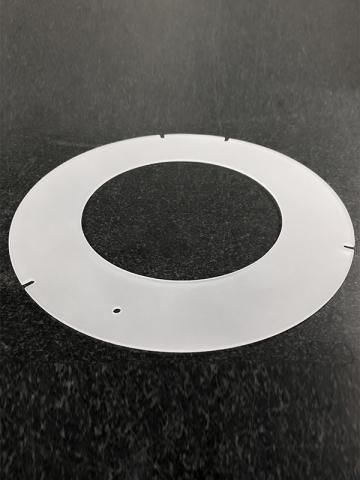

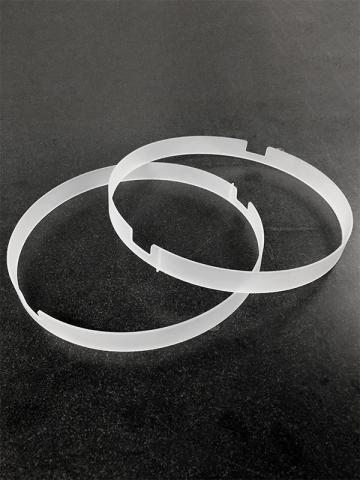

With precise wafer slots and reinforced structural integrity, this boat ensures consistent wafer spacing and alignment, enabling uniform gas flow and heat distribution within oxidation, diffusion, and LPCVD furnace environments. Its smooth surface finish minimizes particle generation and supports cleanroom-grade performance.

The Importance of High Purity in Quartz Wafer Boats

High purity quartz wafer boats are critical components in semiconductor manufacturing, designed to transport and process silicon wafers in high-temperature environments such as diffusion, oxidation, and CVD deposition. Constructed from ultra-high purity quartz (>99.99% SiO₂), these boats minimize metallic and particle contamination, protecting wafer surfaces and ensuring high device yield.

Their excellent thermal stability and low thermal expansion allow them to withstand repeated thermal cycling without deformation or cracking, while maintaining uniform heating across all wafers. The smooth, low-impurity surfaces further reduce particle generation, supporting stringent cleanroom standards and advanced process requirements.

By providing reliable support, chemical inertness, and long-term durability, high purity quartz wafer boats help semiconductor fabs achieve consistent results, higher efficiency, and reduced maintenance costs. They are indispensable for modern semiconductor production and research facilities aiming for maximum precision and productivity.