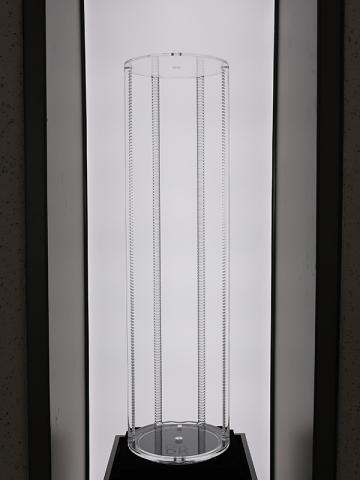

Quartz Boat

Name:

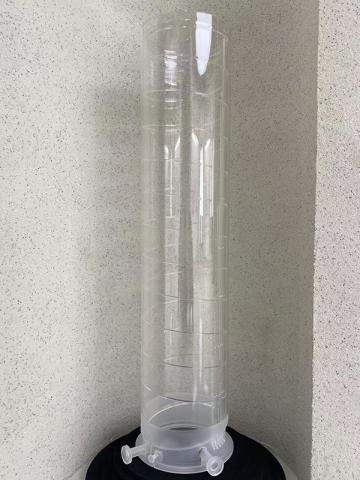

8-inch Vertical Furnace Quartz Wafer Boat

Function & Application:

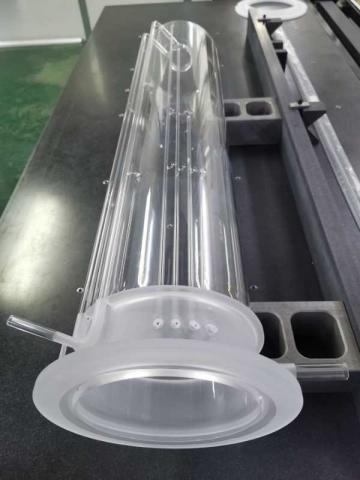

The vertical quartz boat is placed upright inside the quartz tube and serves as a carrier for wafer transport, handling, and processing. Wafers are placed onto the quartz boat and then loaded into the furnace tube for batch manufacturing. It is used in diffusion, oxidation, and CVD deposition processes in wafer manufacturing, which are high-temperature processes.

Performance Requirements:

High temperature resistance, corrosion resistance, excellent thermal stability, high optical transparency, and low impurity content.

-

No.5177 Qianghua West Road, Dongqian Street, Nanxun District, Huzhou City, Zhejiang Province

-

+86-572-3032373

+86-572-3033016

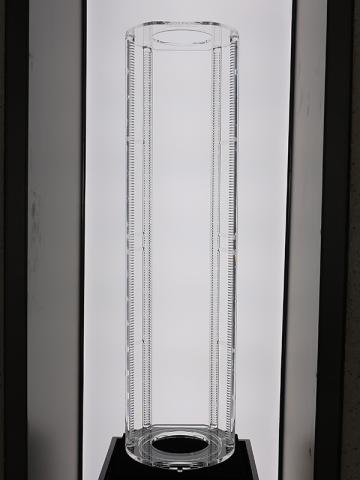

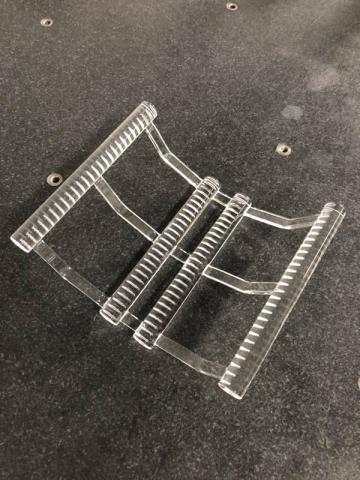

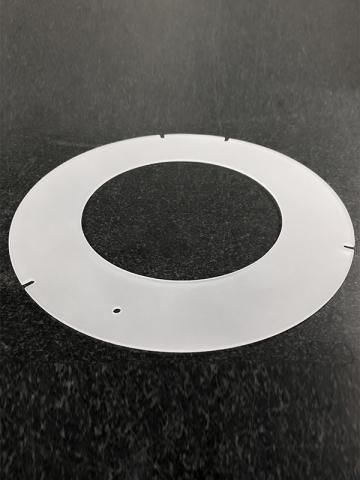

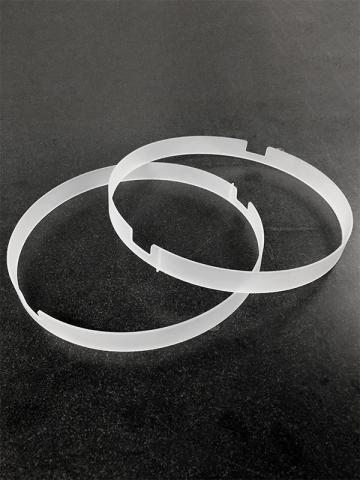

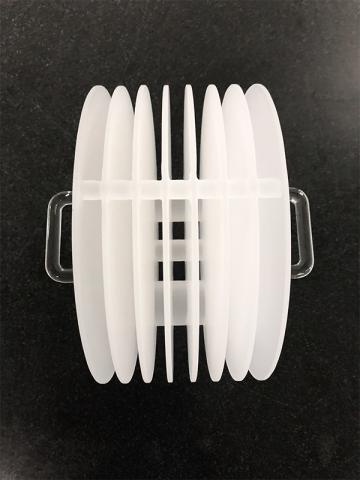

The semiconductor quartz wafer carrier is engineered to safely hold and transport 200 mm wafers through critical high-temperature semiconductor processes, including oxidation, diffusion, and LPCVD. Made from ultra-high-purity fused quartz, it provides excellent thermal shock resistance, low impurity levels, and compatibility with cleanroom environments.

Its precise slot geometry and stable structure ensure uniform wafer spacing, minimizing particle generation, mechanical stress, and thermal distortion during processing. The carrier supports optimized gas flow and heat distribution, producing high yield and repeatable results across all wafers. Designed for integration with vertical and horizontal furnace systems, this quartz wafer carrier is a key component for reliable, contamination-free wafer handling in advanced semiconductor manufacturing.

Role of Quartz Wafer Carriers in Semiconductor Processing

1. Ensuring Wafer Stability and Alignment

Quartz wafer carriers are designed to hold wafers in precise orientations during processes such as diffusion, oxidation, LPCVD, and annealing. Proper spacing and alignment reduce wafer warpage and ensure uniform gas and temperature distribution across the wafer surface.

2. Withstanding High Temperatures

Unlike plastic or metal carriers, fused quartz can withstand temperatures above 1000°C without deformation or contamination. This property makes quartz carriers ideal for vertical and horizontal furnace operations where wafers are subjected to repeated thermal cycling.

3. Maintaining Material Purity

The ultra-high purity of fused quartz prevents the introduction of metallic ions or other contaminants that could compromise device performance. This purity is especially crucial for advanced semiconductor nodes, where even trace contamination can lead to yield loss.

4. Supporting Uniform Process Results

By carefully controlling wafer spacing, quartz carriers enable uniform gas flow and thermal distribution. This contributes to better wafer-to-wafer consistency, reduced defect density, and improved overall yield in semiconductor fabrication.

5. Compatibility with Automation

Modern semiconductor fabs increasingly use robotic wafer handling. Quartz wafer carriers can be customized to meet automation requirements, including robotic transfer, minimizing the risk of wafer breakage while maintaining cleanroom standards.

6. Longevity and Cost Effectiveness

Though quartz carriers require careful handling to avoid mechanical breakage, their long service life under repeated high-temperature cycles makes them cost-effective compared with alternatives.