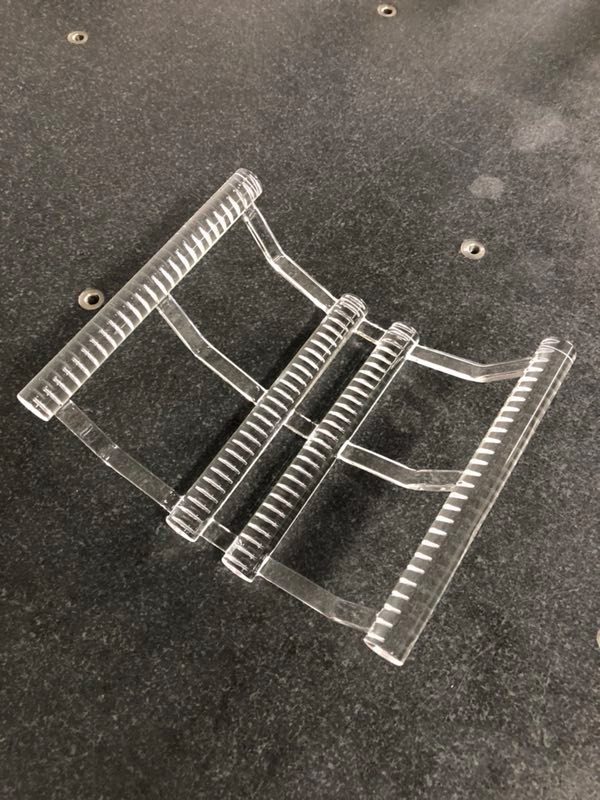

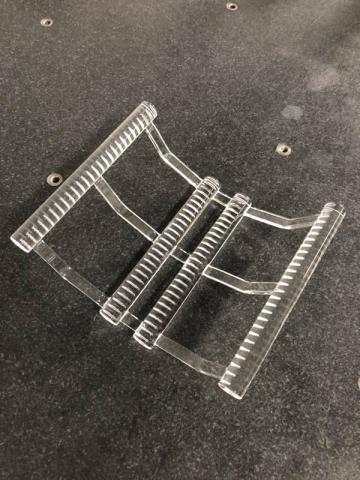

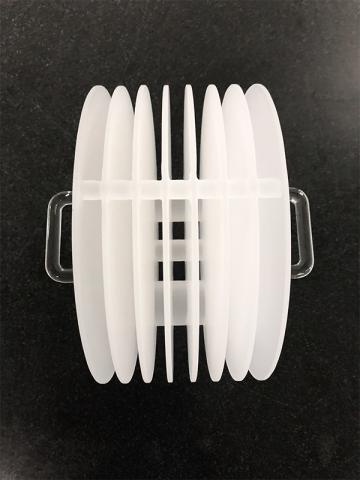

Horizontal Quartz Boat

Name:

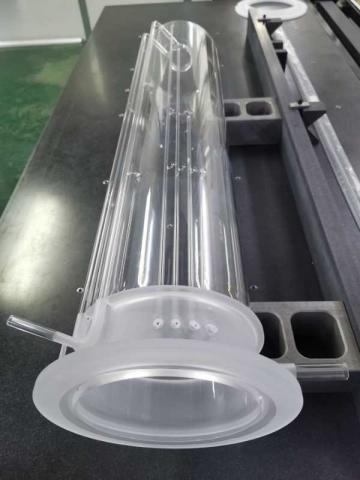

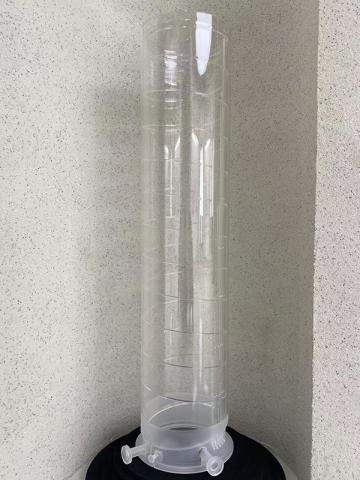

8-inch Horizontal Quartz Wafer Boat

Function & Application:

The horizontal quartz boat is placed horizontally inside the quartz tube and serves as a carrier for wafer transport, handling, and processing. Wafers are placed onto the quartz boat and then loaded into the furnace tube for batch manufacturing. It is applied in diffusion, oxidation, and CVD deposition processes in wafer manufacturing, which are high-temperature processes.

Performance Requirements:

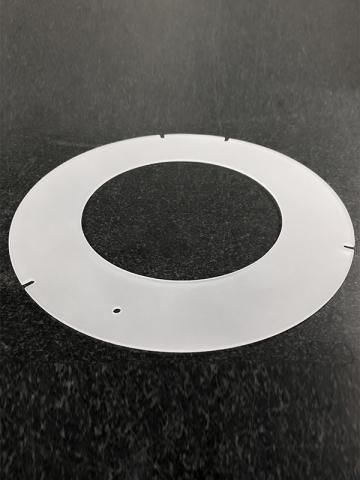

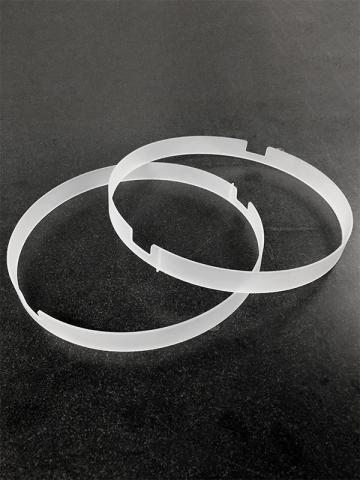

High temperature resistance, corrosion resistance, excellent thermal stability, high optical transparency, and low impurity content.

-

No.5177 Qianghua West Road, Dongqian Street, Nanxun District, Huzhou City, Zhejiang Province

-

+86-572-3032373

+86-572-3033016

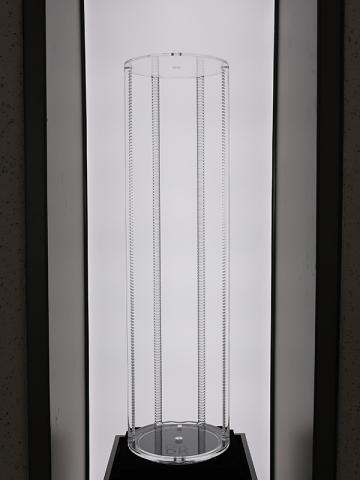

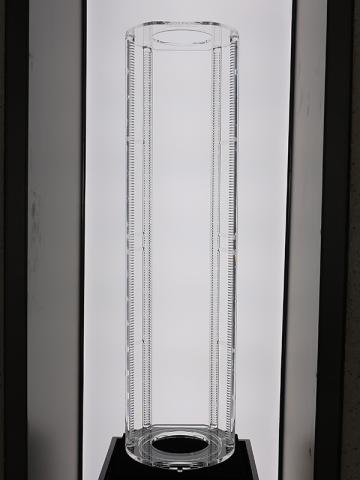

The horizontal quartz boat is purpose-built for secure and precise wafer handling in horizontal furnace systems, widely used for oxidation, diffusion, and annealing processes in 200 mm semiconductor wafer production. Made from high-purity fused quartz, it delivers outstanding thermal stability, corrosion resistance, and dimensional accuracy.

Its horizontal design ensures uniform wafer alignment and spacing along the furnace tube axis, enabling optimized gas flow dynamics and consistent thermal treatment across each wafer. The rigid, low-contamination structure minimizes deformation under high temperatures, helping maintain process integrity and reducing particle generation.

Using Horizontal Quartz Boats in Diffusion, Oxidation, and CVD Applications

Horizontal quartz boats are essential tools in semiconductor manufacturing, designed to securely hold and transport wafers during high-temperature processes such as diffusion, oxidation, and CVD deposition. Made from high-purity fused quartz, these boats ensure minimal contamination, maintaining the integrity of sensitive wafers throughout the process.

The horizontal orientation allows wafers to lie flat, promoting uniform heat distribution and consistent exposure to process gases. This design helps reduce temperature gradients, ensures even doping or oxidation, and improves overall process yield. Smooth, low-impurity surfaces minimize particle generation, supporting cleanroom standards and protecting delicate wafer surfaces.

Durable and thermally stable, high-quality horizontal quartz boats withstand repeated thermal cycling without warping or cracking. By selecting the right horizontal quartz boat, semiconductor fabs and research facilities can optimize wafer uniformity, maximize throughput, and maintain strict process control in diffusion, oxidation, and CVD applications.