NEWS DETAIL

Quartz is widely used in industries such as electronics, optics, telecommunications, and precision instruments due to its excellent physical properties. However, raw or machined quartz often contains internal stress and structural defects, which can lead to cracking, warping, or reduced performance during further processing or final use. Annealing is a crucial step in quartz processing that helps stabilize the material and improve its quality.

This article explains what annealing is, why it is necessary for quartz, how it prevents cracks, the key steps involved, and why it is essential for high-tech applications.

What is Annealing in Quartz Processing?

Annealing is a heat treatment process designed to relieve internal stress and improve the structural stability of quartz. During quartz processing—such as cutting, drilling, grinding, or polishing—mechanical stress and thermal shock can be introduced into the material. These stresses remain inside the quartz as microscopic defects or dislocations within the crystal lattice.

Annealing involves heating quartz to a specific temperature, maintaining it for a period of time, and then cooling it down slowly and uniformly. This controlled heating and cooling allow the quartz crystal lattice to reorganize, reduce internal stress, and eliminate micro-cracks. The result is a more stable and durable quartz product that is better suited for high-performance applications.

Why Quartz Needs Annealing

Quartz has a rigid crystal structure, which makes it strong and resistant to high temperatures. However, this same structure is sensitive to internal stress. The main reasons quartz requires annealing include:

Internal Stress from Manufacturing

Cutting, drilling, and grinding introduce mechanical stress into quartz. This stress can remain trapped in the material and cause cracking later, especially during further processing or thermal cycling.

Thermal Shock

Rapid heating or cooling during production or use can cause thermal shock. Quartz expands and contracts at high temperatures, and if this happens too quickly, internal fractures can develop.

Microscopic Defects

Even small defects in the crystal lattice can reduce the strength and stability of quartz. Annealing helps reduce these defects by allowing the crystal structure to reorganize.

In short, annealing improves the reliability and durability of quartz by removing internal stress and stabilizing its structure.

How Annealing Helps Reduce Cracks

Cracking is one of the most common problems in quartz processing. Cracks can occur during manufacturing, handling, or final use, and they can severely reduce the performance of quartz components. Annealing helps reduce cracks in several key ways:

Stress Relief

The primary benefit of annealing is stress relief. During annealing, the quartz is heated to a temperature that allows internal stress to relax. This reduces the likelihood of cracking during subsequent processing or use.

Improved Toughness

Annealing improves the toughness of quartz by reducing internal defects and strengthening the crystal structure. Tougher quartz is less likely to crack when subjected to mechanical or thermal stress.

Uniform Cooling

Controlled cooling during annealing prevents thermal gradients that can cause new cracks. Slow and uniform cooling ensures the quartz contracts evenly.

By reducing internal stress and stabilizing the crystal structure, annealing significantly lowers the risk of cracks and improves the long-term reliability of quartz products.

Key Annealing Steps: Heat, Hold, Cool

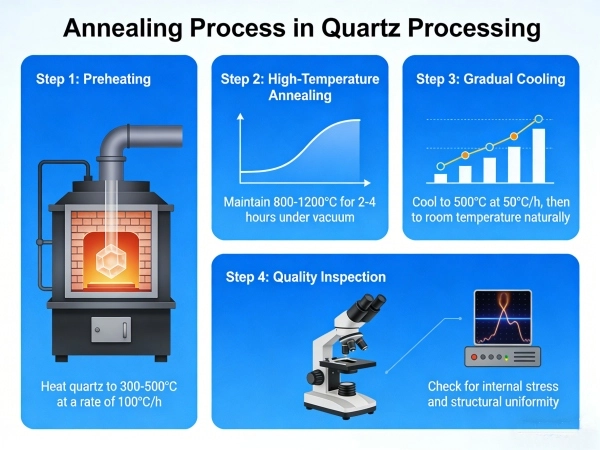

Annealing quartz is a precise process that requires accurate control of temperature and time. The key steps include:

Step 1: Heating

Quartz is heated slowly to the annealing temperature, typically between 600°C and 900°C depending on the type of quartz and its intended use. Rapid heating can cause thermal stress, so temperature must rise gradually.

Step 2: Holding

Once the target temperature is reached, the quartz is held at this temperature for a set period. This allows the crystal structure to stabilize and internal stress to relax. The holding time can vary from several hours to more than a day based on the size and thickness of the quartz component.

Step 3: Controlled Cooling

Cooling is the most critical step. Quartz must cool slowly and evenly to prevent thermal shock and the formation of new stress. Many manufacturers use programmable annealing furnaces with controlled cooling rates.

Proper control of these steps is essential for successful annealing. Any deviation in temperature or cooling speed can lead to incomplete stress relief or new defects.

Why Annealing Matters for High-Tech Uses

Quartz is widely used in high-tech industries such as semiconductors, optics, and telecommunications. These applications require extremely high precision, stability, and reliability. Annealing is essential because:

High Precision Requirements

Quartz components used in optics and semiconductor equipment must maintain precise dimensions and stable properties. Annealing reduces the risk of warping and deformation.

Long-Term Stability

High-tech applications often involve long-term operation under varying temperatures. Annealed quartz is more stable and resistant to thermal cycling.

Improved Performance

Annealed quartz has better mechanical strength and fewer defects, which improves overall performance and reliability. This is critical for applications such as quartz wafers, lenses, and high-frequency resonators.

In conclusion, annealing is not an optional step in quartz processing. It is a necessary heat treatment that ensures the material’s quality, stability, and reliability—especially in high-end applications.