NEWS DETAIL

This article outlines the key factors that define a reliable quartz supplier and explains how buyers can assess long-term capability, technical competence, and operational stability.

Does the Supplier Control the Entire Manufacturing Process?

Manufacturing control is one of the most fundamental indicators of supplier reliability. A quartz supplier that relies heavily on external subcontractors for melting, forming, or machining inevitably faces limitations in consistency, traceability, and response speed. Variations introduced at any outsourced stage can propagate through the production chain, making it difficult to maintain stable quality over time.

A supplier that controls the entire manufacturing process internally is better positioned to manage raw material quality, process parameters, and dimensional accuracy. Full control over casting, thermal processing, and precision machining also enables faster troubleshooting and more reliable delivery schedules. From the customer’s perspective, this level of integration reduces supply risk and ensures greater predictability in both performance and lead time.

Are the Facilities Built for Semiconductor Applications?

Quartz used in semiconductor manufacturing must meet far stricter requirements than quartz used in general industrial applications. Purity, surface integrity, dimensional precision, and contamination control are all critical factors that directly affect process stability inside semiconductor equipment.

Facilities designed specifically for semiconductor applications typically incorporate dedicated production lines aligned with standard wafer sizes and controlled cleanroom environments. Without these conditions, even well-machined components may fail prematurely due to particle contamination or surface defects. A reliable supplier invests in infrastructure that reflects a deep understanding of semiconductor manufacturing demands rather than adapting general-purpose facilities after the fact.

Can the Supplier Support Custom Quartz Requirements?

In semiconductor production, customization is the norm rather than the exception. Tool modifications, process optimization, and new technology nodes frequently require quartz components with unique geometries, tight tolerances, and specific material characteristics. The ability to support such requirements depends not only on machining capability but also on engineering expertise.

A reliable quartz supplier must be capable of developing products directly from customer drawings or samples while understanding how design choices affect thermal behavior, mechanical strength, and service life. This requires a strong R&D foundation and close collaboration between engineering and production teams. Suppliers that lack this depth may deliver parts that meet dimensional specifications but fail under actual operating conditions.

How Does the Supplier Ensure Consistent Product Quality?

Quality consistency is achieved through systematic control, not final inspection alone. Reliable suppliers embed quality assurance throughout the entire production process, beginning with raw material evaluation and continuing through forming, machining, and final verification.

In-house testing laboratories and advanced inspection equipment allow suppliers to verify critical parameters before products are shipped. This internal verification capability provides customers with confidence that quality is measured, documented, and repeatable. In industries where downtime is extremely costly, the ability to rely on verified quality is far more valuable than post-delivery problem resolution.

Are Certifications and Long-Term Customer Approvals in Place?

Management system certifications and customer approvals serve as external validation of a supplier’s operational maturity. Certifications such as ISO 9001, ISO 14001, and ISO 45001 indicate that quality, environmental responsibility, and occupational safety are managed through formalized systems rather than ad hoc practices.

Equally important is a supplier’s track record with established customers. Long-term cooperation with leading semiconductor companies reflects consistent performance under demanding conditions. Reliability is not demonstrated by isolated projects but by sustained partnerships built over many years of production and continuous improvement.

Can the Supplier Support Long-Term Growth and Innovation?

The semiconductor industry evolves rapidly, and supplier reliability must extend beyond current capabilities. A supplier that does not invest in innovation risks becoming obsolete as process requirements change.

Long-term reliability is closely linked to ongoing R&D efforts, proprietary technology development, and collaboration with academic or research institutions. These activities enable suppliers to refine materials, improve processes, and respond effectively to new technical challenges. For customers, working with an innovation-oriented supplier ensures continuity and adaptability in future production cycles.

Why DKEQ is a Reliable Quartz Supplier

DKEQ was built around the exact principles outlined above.

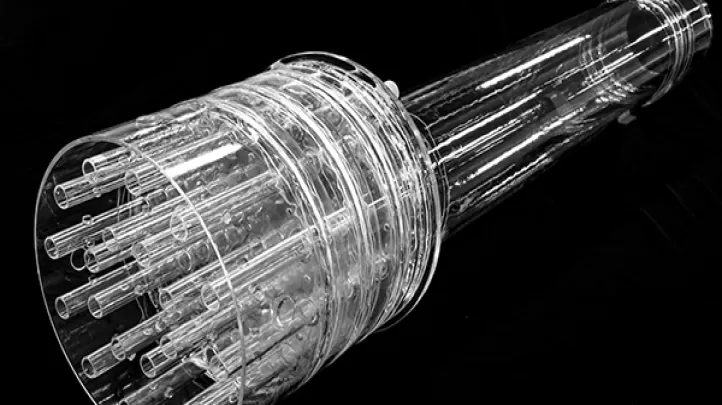

1. With two in-house quartz casting foundries and a dedicated CNC machining factory

2. Includes complete 6-inch, 8-inch, and 12-inch production lines and Class 100 cleanrooms

3. Supports development based on customer drawings or samples

4. Ensures stable and verifiable product quality

5. Has ISO 9001, ISO 14001, and ISO 45001

6. Long-term cooperation with leading semiconductor companies for more than 20 years

7. With institutions such as Harbin Institute of Technology, Shandong University of Technology, and Huzhou University

Our quartz products can be widely used in semiconductors, aerospace, military applications, and photovoltaics—industries where reliability is non-negotiable. DKEQ is a partner worth considering.