Semicon

What is semiconductor quartz?

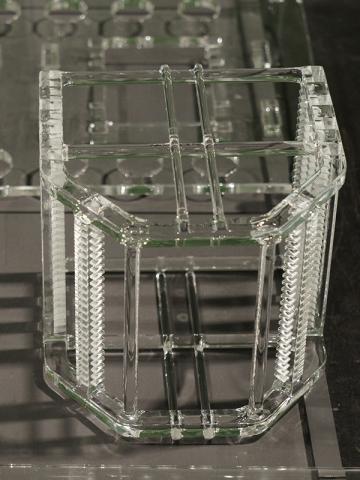

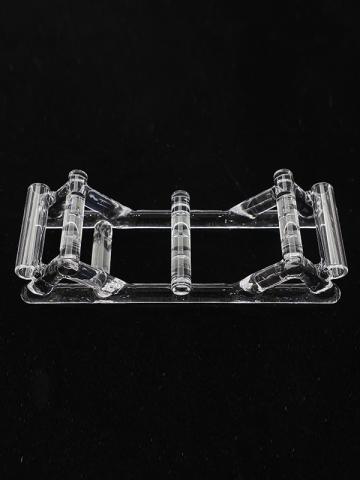

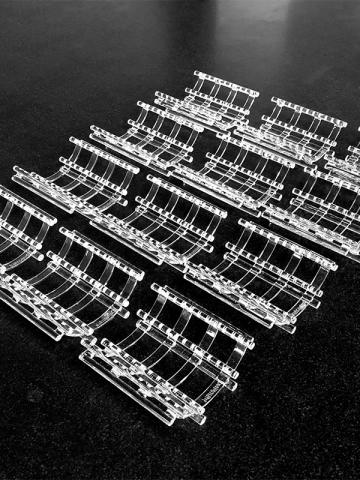

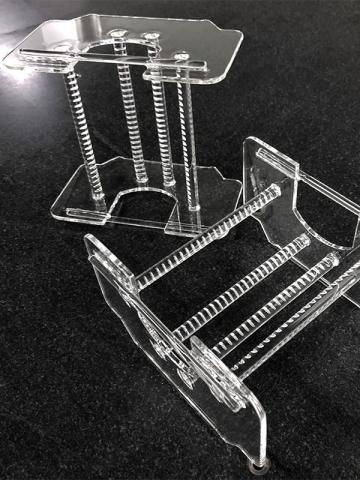

Semiconductor quartz refers to highly purified quartz with extremely high purity, used as critical materials and equipment components in semiconductor manufacturing, such as quartz crucibles, quartz tubes, quartz rods, and quartz parts in photolithography and etching equipment.

Why is quartz important in semiconductor industry?

The semiconductor industry uses quartz primarily because of its extremely high purity, excellent high-temperature resistance, strong chemical inertness, and superior electrical insulation properties. These characteristics meet the stringent requirements for material cleanliness and stability in semiconductor manufacturing processes, thereby ensuring the quality and reliability of the produced semiconductor devices.

Rapid development of the semiconductor industry has driven the demand for high-end quartz materials......this growth has led to more complex and precise manufacturing processes, imposing higher requirements on the purity, performance, and stability of materials. To meet these demands, high-end quartz materials, with their extremely high purity, excellent thermal stability, and chemical inertness, have become indispensable key materials. As chip fabrication processes continue to scale down and technology advances, the application ratio and technical content of high-end quartz materials in equipment have significantly increased, thereby driving sustained growth in demand for these materials.

On each product category page, we display many different models. These are all orders from our previous customers, and we can make the same styles. Please take your time to browse through them. And if you find one that meets your needs, please contact us as soon as possible!

FAQs

1. Do you offer OEM services for your semiconductor quartz?

Yes, we offer OEM services for our semiconductor quartz products. You can give us your design of semiconductor quartz. We will try our best to meet your specific requirements.

2. What is the delivery time for your products?

Producing seminconductor quartz is a complex process, especially clients have special needs. So, the delivery time may vary depending on the order quantity and customization requirements. We will work with you to provide an accurate delivery timeline for the order.